Mining Mill Use For Coal Crushing

6 Types of Coal Crusher: Which Is Best for

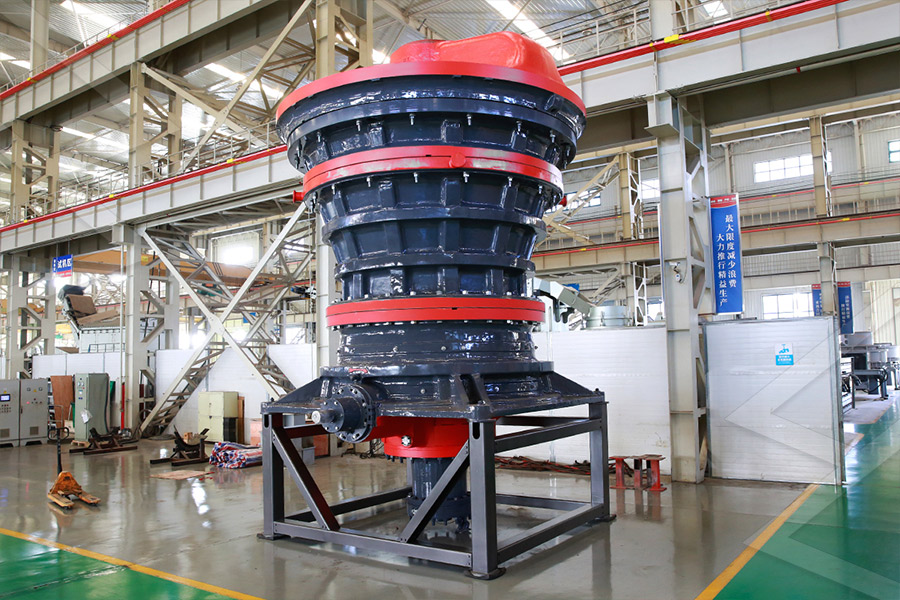

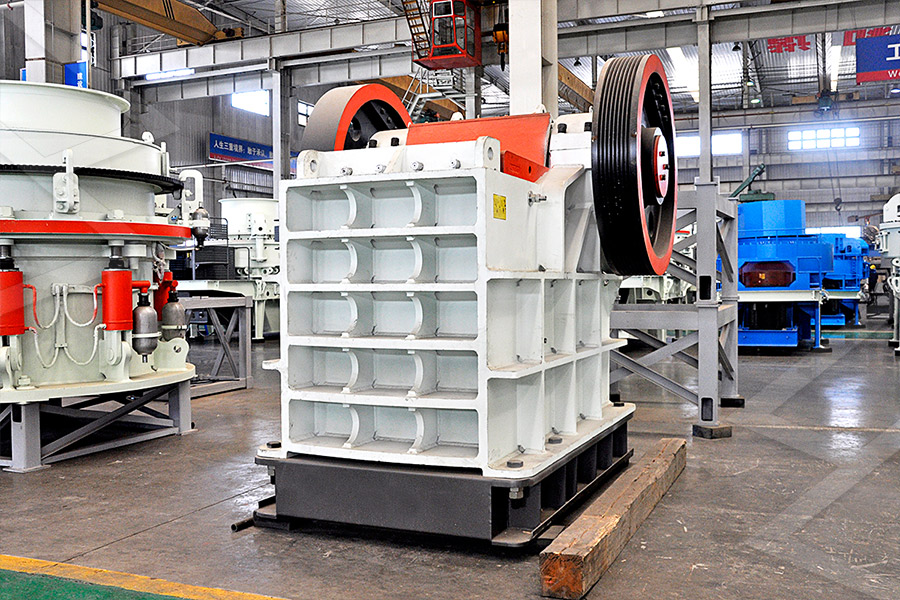

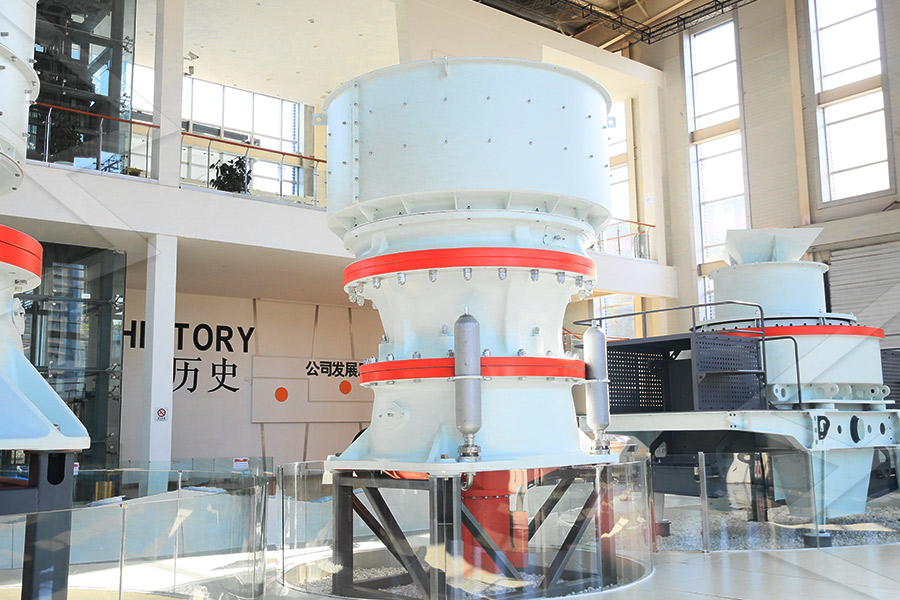

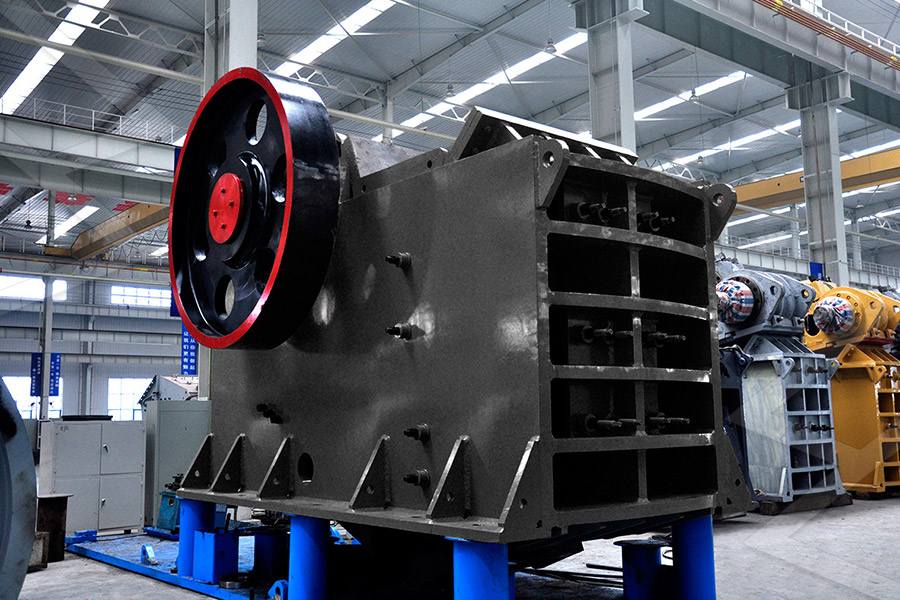

2023年10月8日 — 1 Jaw crusher The jaw crushers are popular primary crushers for coal They are often used in mines and quarries where large amounts of coal are mined The working principle of the jaw crusher is to 2017年6月2日 — Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material Grinding equipment can How it Works: Crushers, Grinding Mills and 2024年9月25日 — Grinding mills, including ball mills, pebble mills, and semiautogenous grinding (SAG) mills, are essential for reducing crushed ore into finer particles The material is fed into mills where it is broken down further, preparing it for downstream processes like flotation or leachingMining Crushers, Breakers Grinding Mills for the Mining Coal Mining Solution liming is a coal mining machine manufacturer in China, supplies all kinds crushing machines and design coal crushing production line according to machines used for coal mining – Grinding Mill ChinaMachine Use In Coal Mining Crusher Mills

.jpg)

Crushing Plant Design and Layout Considerations

2024年9月24日 — In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimumPulverizers Coal Grinding Roller Mills William’s Vertical Roller Mill Pulverizers utilize centrifugal force to grind coal particles while maintaining low operating costs This product features easily replaceable wear parts, Coal Crushers Coal Pulverizers Mills2024年3月12日 — The energy problem One of the most pressing issues in crushing and grinding is the sheer amount of energy these processes use They account for around 56% of the mining sector’s total energy usage – Exploring AI’s potential in optimising crushing 2021年6月24日 — TABLE OF CONTENTS Chapter Subject / section name Preface Table of Contents Metso’s Mining and Construction Technology 1 Quarry Process + Process Integration and Optimization (PIO) 2 Feeders 3 Crushing Equipment 3 CSeries Jaw Crushers 3 Superior MKII Primary Gyratory Crushers 3 GP Series Cone Crushers 3 MP Crushing and Screening Handbook AusIMM

.jpg)

Crushing Plant Design and Layout Considerations

2024年9月24日 — %PDF12 %âãÏÓ 114 0 obj /Linearized 1 /O 116 /H [ 1107 524 ] /L /E 29615 /N 29 /T >> endobj xref 114 34 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 2015年12月26日 — In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant Crushing in Mineral Processing 911Metallurgist2018年12月26日 — 9 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance In this way the crushing gap located between the fixed concaves in the crusher shell and the eccentrically gyrating mantle continuously changes The feed material that is fed into the crushing chamber from above is Construction, Working and Maintenance of Crushers for 2019年6月21日 — The mine was able to cut its electrical power consumption by 30% by applying vertical mills instead of ball mills in its regrind circuit The mine opted to install 16 Vertimill VTM1500WB Grinding down energy consumption in comminution MINING

Types of Crushers Explained: Everything You Need to Know

2024年4月19日 — Atrition crushing is great for the production of very fine particle sizes and it is commonly used in mineral processing and mining for grinding ore Shear Crushing: Shear crushing takes a shearing force and applies it to the material, which results in the formation of cracks on the weak planes This method is not frequently used in rock Professional Manufacturer of Coal Crusher, Coal Mill, Coal Crushers, Coal Crushing Plant,Coal Crusher Machine What Is Propofol–and How Could It Have Killed Michael The King of Pop's doctor, Conrad Murray, is on trial for involuntary manslaughter, but could propofol alone have caused MJ's death?what is coal mill Mining Quarry Plant miningcrushingMining coal Coal miners use large machines to remove coal from the earth Many US coal deposits, called coal beds or seams, are near the earth's surface, but others are deep undergroundModern mining methods allow US coal miners to easily reach most of the nation's coal reserves and to produce about three times more coal in one hour than in 1978Coal mining and transportation US Energy Information 2013年4月22日 — coal mobile crusher india, mining equipment cost "the top world wide coal mobile crusher india offer you the best pricing for the best mining equipment" mobile crusher coal kefid Mining Machinery is a professional material processing designer and supplier in the world, we have excellent research and development group to provide our mobile coal crusher Mining Quarry Plant

.jpg)

coal pulverising mill types Mining Quarry Plant

2013年4月1日 — Find the Right and the Top Various types of coal mill for your coal handling plant! Schumacher, Glenn (201) Coal Pulverising Mill Types ISBN 9780646537597Stedman offers size reduction solutions for industries such as asphalt recycling, aggregate crushing, Minerals Mining, Ceramic brick clay crushing and more! Selecting the proper equipment for your project can Industrial Crushing Equipment Pulverizing Mill 2019年1月14日 — The city is home to two international mining giants, Glencore and Vale, as well as about 40 other smaller mining and exploration companies There are 15 operating mines, two mills, two smelters and a Crushing comminution: decarbonising mining’s Hammermill Crushers are known to generate material finer than 3/16" (4mm), which in some applications may be undesirable However, if there is a market for finer material, or if it is acceptable within the desired product size, Hammermills can achieve reduction ratios that may otherwise require multiple crushersHammermill Crushers McLanahan

.jpg)

The Complete Guide to Primary Crushing, Secondary Crushing

2023年2月28日 — 500t/h Coal Gangue Mobile Crushing Plant; 450t/h Stone Mobile Crushing Plant; This makes it ideal for use in highcapacity crushing plants However, primary crushing also has its disadvantages, including high energy consumption and the risk of overcrushing the material, which can lead to the formation of fines and result in a lowerquality 2021年3月25日 — The right one for a primary crushing application depends on the material to be crushed, the feed size, the desired product size and the capacity required Primary crushers reduce large runofmine material, such as rocks and ore lumps, into smaller sizes for further processing downstream, whether that be transport to additional crushers or What Type of Crusher Is Best for Primary Crushing?2024年7月26日 — We are the standard of comparison for central stations, industrial power plants, and mine preparation plants around the world We make many types of coal crushing equipment, like our ACC Series Rolling Ring Crusher with capacities ranging from 630–2,350 TPH We also offer hammermills, impactors, double and singleroll crushers, Coal Crushers, Shredders, Mills for Mining Power 2022年5月9日 — 2 Underground Coal Mining Technologies 21 Present Technologies 211 Semi Mechanized Methods: Currently, most of CIL mines using Bord Pillar remove coal from the face by blasting deploy SDL or LHD for loading and transportation of coal in the active mining areas Coal transportation to surface is either by a series of beltTechnology Roadmap for Coal Sector Ministry of Coal

.jpg)

Iron Ore Processing: From Extraction to Manufacturing Mining

2024年4月26日 — b Autogenous and SemiAutogenous Mills: In some cases, autogenous (AG) and semiautogenous (SAG) mills are used for grinding These mills utilize the ore itself as the grinding media, reducing the need for additional grinding media AG/SAG mills are typically used for coarse grinding, where large pieces of ore are efficiently broken down2010年7月1日 — The Mine to Mill concept (looking at the relationship between blast fragmentation and crushing and comminution energy) has changed the way engineers look at the total project comminutionThe Evolution of Crushing and Grinding: Changes in the MINING2013年1月1日 — Impactor mills Hammers strike falling coal particles, and throw them against the impactor plates for further breakage Crushing and sizing of coal at the mine and preparation plant is primarily intended to facilitate the removal of ashforming and sulfurbearing minerals, and so concentrates on using sieving and classification to produce Coal comminution and sizing ScienceDirectCoal mining Wikipedia Coal mining is the process of extracting coal from the ground Coal is valued for its energy content, and, since the 1880s, has been widely used to generate electricity Steel and cement industries use coal as a fuel for extraction of iron from iron ore and for cement productioncoal scoops underground mining KOOKS

.jpg)

Metallurgists Mineral Processing Engineers

911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has 2020年1月9日 — The main conveying equipment is a belt conveyor In the process of mining, unloading, separation and conveying, the pulverized coal and dust escape into the air, causing environmental pollution Recent Patents on Roll Crushing Mills for Selective Crushing of Coal 2020年1月31日 — Gangue is the concomitant product of coal mining The traditional approach for gangue treatment is to transport it from underground to ground level to accumulate and form gangue hills On the basis of summarizing previous research results, this paper introduces the hydraulic roller crusher and the electric machine builtin coal Recent Patents on Roll Crushing Mills for Selective Crushing of Coal The raw coal is then fed into the pulverizer where it is ground into fine coal particles What are the Advantages of Pulverized Coal? Pulverized coal produces a larger amount of heat than traditional coal This leads to more fuelefficient and easiertoburn lowgrade fuel sources This type of coal fineness increases the surface area for burningCoal Crushers Coal Pulverizers Mills Williams Crusher

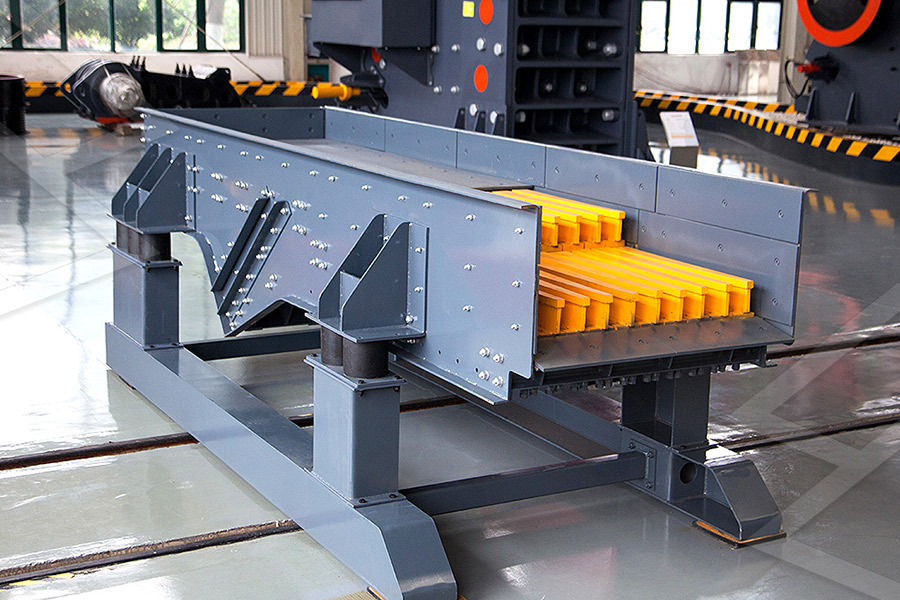

OPERATION AND MAINTENANCE OF CRUSHER HOUSE

2015年4月10日 — Coal crushing equipment of coal handling plant system in the thermal power plant is very important for Plant efficiency improvement Keywords: India coal grades, Crusher, Construction, Crushing stages, Defect identification INTRODUCTION The coal handling plant (CHP) in a thermal power station covers unloading of coal, its2024年3月1日 — A stone crushing plant needs essential primary crushers like jaw and gyratory crushers as well as finecrushing equipment like impact crushers and ball mills Other critical heavyduty machines for the effective operation of a stone mill include the belt conveyors, vibration feeder, vibrating screens, and a central control system for all these What Machines Do Stone Crushing Plants Need? Fote 2018年1月18日 — To eliminate the prearranged pillars, control the subsidence and collapse and promote the widespread use of coal auger mining method in thin or extremely thin coal seam, Li and Yang [23] [24][25 Recent Patents on Gangue Pneumatic Filling for Coal Auger Mining 2023年10月19日 — Manganese steel castings are currently being extensively used for stonecrusher in the crushing and mining sector globally The higher manganese content in AMS is considered to be one of the oldest materials having an enriched amount of hardness, toughness, and ductility, due to which same can be used for the variable load high impact Critical Analysis of Manufacturing of Manganese Steel Liners

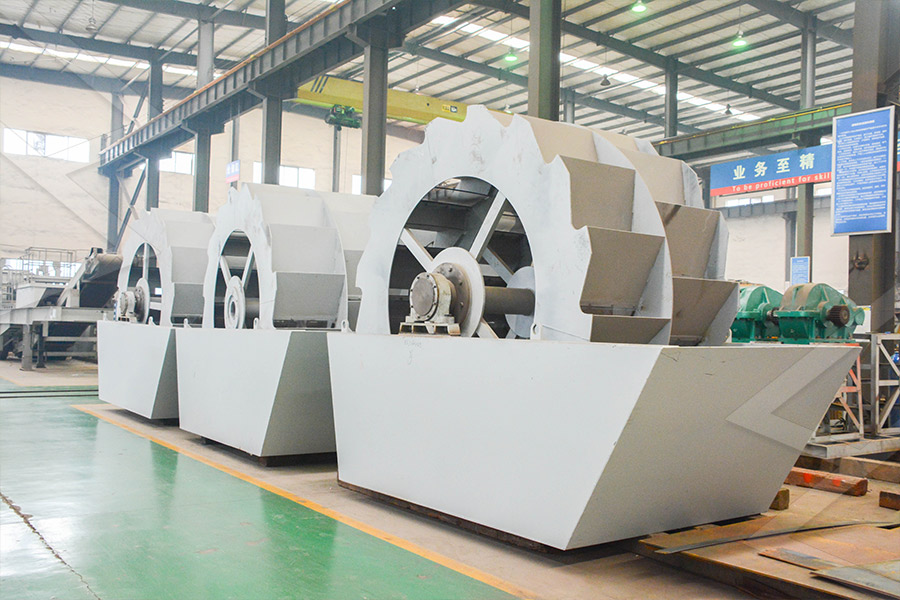

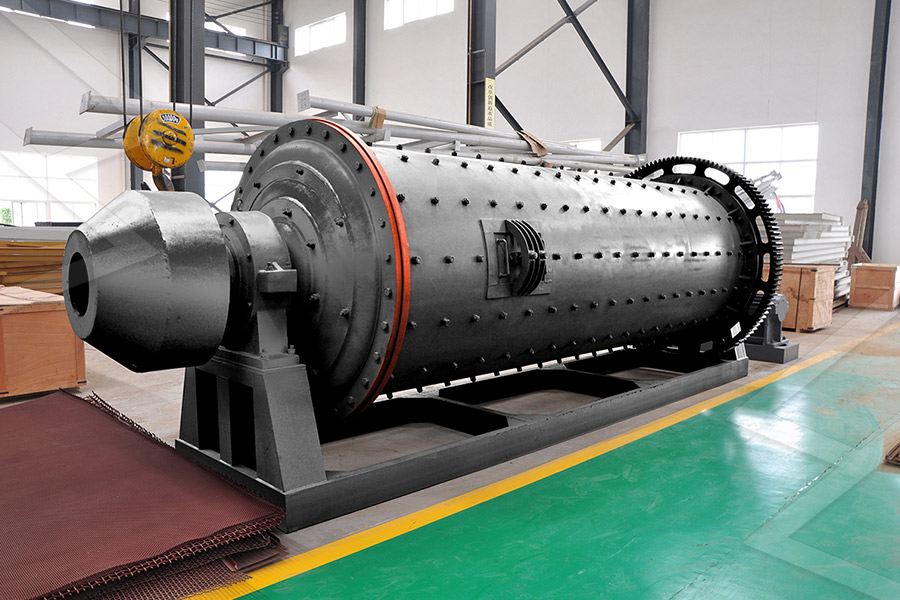

How coal gets crushed in ball mills? LinkedIn

2023年11月7日 — Coal is typically crushed in ball mills to prepare it for combustion in power plants or other industrial processes The process involves several steps: ball mills Mining: Coal is first extracted 2013年3月15日 — Mining crushers mainly include jaw crusher, cone crusher, impact crusher, mobile crusher for crushing stone, Coal grinding equipment sale in Korea best korea crushing equipment Mining Quarry PlantThis means that the number of crushing stages can be reduced depending on the feed size accepted by primary grinding stage Image of a “Classical” 3stage ore crushing prior to rod mill [image: (13551)] Diagram of AMIT 135: Lesson 5 Crushing – Mining Mill Vertical coal mill is also called LM series vertical roller mill, and is also widely used in mineral grinding mill industry Vertical coal mill is big in appearance with high capacity Raymond Mill is the eary grinding mill, but now is still used widely Coal beneficiation process About Coal Beneficiation, there are three kinds of processes coal pulverising mill types Grinding Mill China

Construction, Working and Maintenance of Crushers for

2018年12月26日 — 9 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance In this way the crushing gap located between the fixed concaves in the crusher shell and the eccentrically gyrating mantle continuously changes The feed material that is fed into the crushing chamber from above is 2013年3月28日 — Professional Manufacturer of Coal Crusher, Coal Mill, Coal Crushers, Coal Mills, Coal Mining Equipment, Coal Mobile Crusher, Coal Crushing Plant Crusher Mills, Cone Crusher, Jaw Crushers – Liming Heavy Industrycrusher and mill used Mining Quarry Plant2024年1月11日 — 1 To pulverize crushed coals in a ball mill, you start by feeding the mill with crushed coal Then the grinding media crushes and grinds the coal in the rotating chamber 2 Airflow carries the pulverized coal out of the ball mill 3 Next, you'll need to use the mill classifier to separate the fine coal particles from the airflowHow to Process Coal into Pulverized Coal in 5 Steps?3 天之前 — Comminution, consuming close to 40% of total energy contains a single piece of equipment—the grinding mill—that is typically the largest single consumer in a mining operation Noting that the comminution area also includes crushing, pumps and other equipment—the grinding mill(s) are normally the largest single energy consumerMINING ENERGY CONSUMPTION 2021 CEEC (Coalition for

Use of drilling performance to improve rockbreakage

2020年3月1日 — Drilling performance data can provide a viable means of characterizing the rock mass for MTM The use of blasthole drilling data is advantageous since it is acquired systematically, routinely, and in real time [9]In the mining industry, monitoring while drilling (MWD) is a standard practice for obtaining penetration rate (PR), rotational speed, 2024年3月12日 — The energy problem One of the most pressing issues in crushing and grinding is the sheer amount of energy these processes use They account for around 56% of the mining sector’s total energy usage – Exploring AI’s potential in optimising crushing 2021年6月24日 — TABLE OF CONTENTS Chapter Subject / section name Preface Table of Contents Metso’s Mining and Construction Technology 1 Quarry Process + Process Integration and Optimization (PIO) 2 Feeders 3 Crushing Equipment 3 CSeries Jaw Crushers 3 Superior MKII Primary Gyratory Crushers 3 GP Series Cone Crushers 3 MP Crushing and Screening Handbook AusIMM2024年9月24日 — %PDF12 %âãÏÓ 114 0 obj /Linearized 1 /O 116 /H [ 1107 524 ] /L /E 29615 /N 29 /T >> endobj xref 114 34 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n Crushing Plant Design and Layout Considerations

Crushing in Mineral Processing 911Metallurgist

2015年12月26日 — In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant 2018年12月26日 — 9 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance In this way the crushing gap located between the fixed concaves in the crusher shell and the eccentrically gyrating mantle continuously changes The feed material that is fed into the crushing chamber from above is Construction, Working and Maintenance of Crushers for 2019年6月21日 — The mine was able to cut its electrical power consumption by 30% by applying vertical mills instead of ball mills in its regrind circuit The mine opted to install 16 Vertimill VTM1500WB Grinding down energy consumption in comminution MINING2024年4月19日 — Atrition crushing is great for the production of very fine particle sizes and it is commonly used in mineral processing and mining for grinding ore Shear Crushing: Shear crushing takes a shearing force and applies it to the material, which results in the formation of cracks on the weak planes This method is not frequently used in rock Types of Crushers Explained: Everything You Need to Know

what is coal mill Mining Quarry Plant miningcrushing

Professional Manufacturer of Coal Crusher, Coal Mill, Coal Crushers, Coal Crushing Plant,Coal Crusher Machine What Is Propofol–and How Could It Have Killed Michael The King of Pop's doctor, Conrad Murray, is on trial for involuntary manslaughter, but could propofol alone have caused MJ's death?Mining coal Coal miners use large machines to remove coal from the earth Many US coal deposits, called coal beds or seams, are near the earth's surface, but others are deep undergroundModern mining methods allow US coal miners to easily reach most of the nation's coal reserves and to produce about three times more coal in one hour than in 1978Coal mining and transportation US Energy Information 2013年4月22日 — coal mobile crusher india, mining equipment cost "the top world wide coal mobile crusher india offer you the best pricing for the best mining equipment" mobile crusher coal kefid Mining Machinery is a professional material processing designer and supplier in the world, we have excellent research and development group to provide our mobile coal crusher Mining Quarry Plant