Jaw Crusher Site Installation

Jaw crushr operate manual: how to install, repair

2024年9月18日 — To install the jaw plate of the assembled jaw crusher, it needs to be firmly attached to the jaw bed, and soft metal is used as a gasket to ensure that it is leveled and then tightened with bolts before useTo ensure the efficient operation of a jaw crusher, proper installation is crucial This article will provide a detailed explanation of the jaw crusher installation process, including a Jaw Crusher Installation Process Diagram – stone cruxderPage 3: Nordberg C Series Jaw Crushers NORDBERG C SERIES JAW CRUSHERS CHAPTER This manual is valid for the Nordberg C Series Jaw Crushers manufactured METSO NORDBERG C SERIES INSTRUCTION MANUAL Pdf By following these steps, you can successfully install a jaw crusher and ensure that it operates safely and efficiently Always refer to the manufacturer’s manual for specific A StepbyStep Guide to Installing a Jaw Crusher

.jpg)

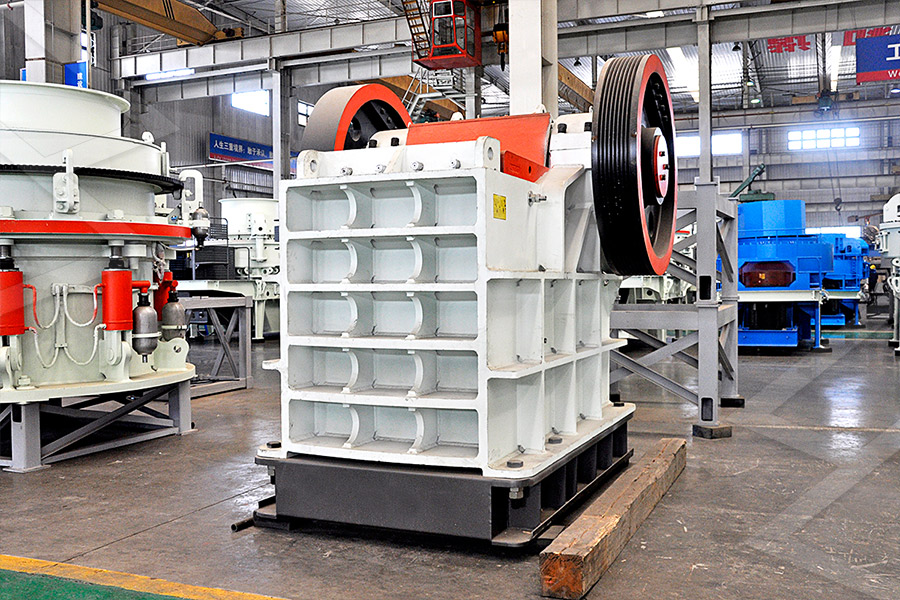

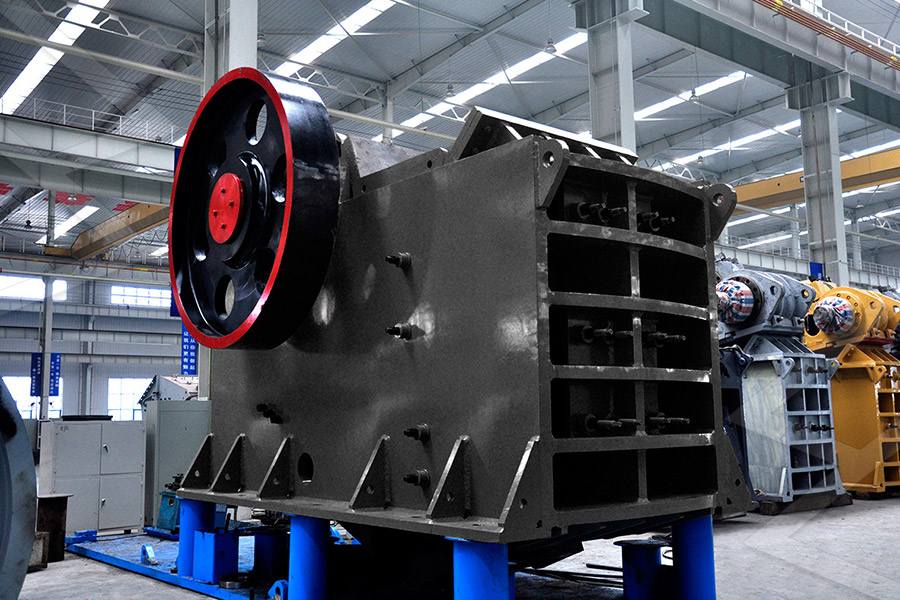

Installation of Jaw Crusher Skills and Notes

The skills and notes of the installation of jaw crusher, the parts how to install, such as frame, shaft and bearing, connecting rod, toggle plate2018年10月15日 — C Series™ jaw crusher basic concepts The jaw crusher is a compression type crusher Feed material is crushed between fixed and movable jaw dies Large Metso Nordberg® C Series™ jaw parts4 天之前 — Jaw Crusher Installation The jaw crusher is a large crusher installed and receives noload testing in the manufacturer's workshop However it is disassembled into C5X Jaw CrusherSBM Industrial Technology Group2021年7月16日 — Crusher automation is easy to install and is provided as complete package including interface to all selected options such as crusher motor starter, hydraulic Nordberg® C Series™ jaw crushers Proven reliability and

.jpg)

jaw crusher 百度百科

Jaw crusher can reach the crushing ratio of 46 and the shape of final product is even It is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc2014年4月1日 — The life of wear parts increases A jaw crusher usually wears more manganese steel per crushed tonne than a gyratory crusher The installation also calls for chutes and other bypass arrangements, Below the surface: Setting up an underground Czech company DS Holding purchased a Sandvik QJ341 jaw crusher and QE241 scalper to increase their operational capacity Looking to invest in mobile equipment to move around sites to recycle construction materials QJ241 Mobile Jaw Crusher Compact Jaw 2024年9月26日 — The Cedarapids® CRJ3042 plant combines the popular JW42 jaw crusher with a high stroke, 42” x 20’ (1067 x 6096 mm) vibrating grizzly feeder resulting in a high production portable crushing machine Learn More about CRJ3042; MJ42 The MJ42 features the rugged JW42 Jaw Crusher for high production applicationsCedarapids JW42 Jaw Crusher Terex MPS

Nordberg® C SeriesTM jaw crushers Metso

2020年7月24日 — lifetime of the jaw crusher Nordberg C Series jaw crushers are modular for quick, easy installation and commissioning in new plants and when replacing old jaw crushers This minimizes onsite engineering and fabrication, saves time, and reduces installation and structural costs The integral motor base reduces space requirements andPage 6 Nordberg C Series Jaw Crushers Table of Contents OPERATING INSTRUCTIONS 41 PREPARATIONS BEFORE STARTING41 42 STARTING THE CRUSHER Page 7 Nordberg C Series Jaw Crushers Table of Contents 54 INSTRUCTIONS FOR LIFTING A JAW CRUSHER WHEN REPLACING CRUSHER SUPPORT BRACKET DAMPERS 5 METSO NORDBERG C SERIES INSTRUCTION MANUAL Pdf 2023年3月2日 — C Series jaw crushers can be customized with options for any application Safe flywheel and drive guards protect operators from moving objects An optional integrated motor base allows installation of the crusher drive motor directly to the back of the crusher The motor moves in sync with the crusher so the Vbelt life is enhanced and Metso Crushing and screening solutions aggnetJaw crushers are widely used in mining smelting, building materials, roads, railways, water conservancy, and chemical industries There will be a strong vibration in the work, because of the large hardness of crusher materials Therefore, the work of the installation of a jaw crusher is very importantInstallation of Jaw Crusher Skills and Notes JXSC Mine

AIMIX Mobile Crusher For Sale Wheel Crawler Type

Mobile Crushing Plant For Sale A mobile crushing plant is a complete set of mobile equipment designed to crush and screen various materials onsite It consists of a vibrating feeder, a jaw crusher, an impact crusher or cone crusher, a vibrating screen, and belt conveyorsThe mobile crusher plant is highly flexible and can be easily relocated The singletoggle jaw crusher has less shafts and bearings compared to doubletoggle jaw crushers Only one toggle goes from the bottom of the swinging jaw back to the fixed point Doubletoggle jaw crushers In a doubletoggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear toggles up and downWhat Are Jaw Crushers and How Do They Work? OreflowNordberg® C Series™ jaw crushers are designed modular to save time and installation costs They can be installed within a few days, minimizing onsite engineering and fabrication The jaw crushers can be upgraded with crusher automation that enable monitoring and adjusting the settings of a feeder, crusher, and conveyor remotelyNordberg® C Series™ jaw crushers Metso2021年2月1日 — Simple installation Adaptable mounting arrangement suitable for static or mobile installation Easy adjustment Full hydraulic CSS adjustment through MJ42 JW42 (30” x 42”) Jaw Crusher, 40” x 14’ Feeder 150 hp (110 kW) 155480 (140435) (3) 40ft shipping containers MJ55 JW55 (32” x 55”) Jaw Crusher, 52” x 20’ Feeder 200 hpJaw Crushers JW Series Terex

Proven reliability and performance Nordberg® C

2023年6月2日 — attached during installation C Series jaw crushers are also easy to install in underground mining applications as the modular design allows them to be dismantled for transportation in tight spaces Mounting the crusher does not require anchor bolts This is due to our unique solution where the crusher is standing on its2024年2月18日 — The jaw crusher diagram is instrumental when it comes to adjustments for altering the granularity of the output One critical metric is the Closed Side Setting (CSS)—the smallest gap between the jaws Jaw Crusher Diagram: Simplified Guide JXSC2024年7月12日 — The jaw crusher should be installed on a concrete foundation, and in order to reduce vibration, wooden or rubber pads should be added between the foundation and the frame Operation: Correct operation is one of the important factors to ensure the continuous and normal operation of the crusher Improper operation or negligence during the Installation, operation and maintenance of jaw crusherEASY TO INSTALL AND TRANSPORT Nordberg® C120™ jaw crusher has a range of bolton options, including an onboard motor base and guarding for the flywheel and drives, made from specially developed composite materials The unit is simple to install as a single crusher or as a complete module in a new or existing plantNordberg® C120™ jaw crusher Metso

.jpg)

Proven reliability and performance Nordberg® C

2024年4月30日 — attached during installation C Series jaw crushers are also easy to install in underground mining applications as the modular design allows them to be dismantled for transportation in tight spaces Mounting the crusher does not require anchor bolts This is due to our unique solution where the crusher is standing on its3 天之前 — DOVE Jaw Crushers are ideal rock crusher machines, highly efficient and economical for handling Primary and Secondary stone crushing applications of various ores and bulk materials with compressive strength below 320 MPaDOVE Crushers are supplied in Stationary complex plant configuration, or in Portable and Mobile configuration Jaw Crusher Crushing Plant Hard Rock Mining Equipment2024年4月3日 — Installation drawings Quality reference materials enabling systematic work Robust planning mitigates risks during crusher installation and commissioning phases Installation Video of HGT Gyratory Crusher 2 Site Preparation Preparing the installation site is crucial: Clear area within 10m radius and level with compacted gravel/cementA Comprehensive Guide to Stone Crusher Installation2024年7月9日 — In conclusion, the installation of a jaw crusher is a multifaceted process that demands attention to detail and adherence to technical specifications From site preparation and foundation construction to assembling main components and establishing electrical and hydraulic connections, each step plays a pivotal role in ensuring the crusher’s What Are The Key Steps In Jaw Crusher Installation?

.jpg)

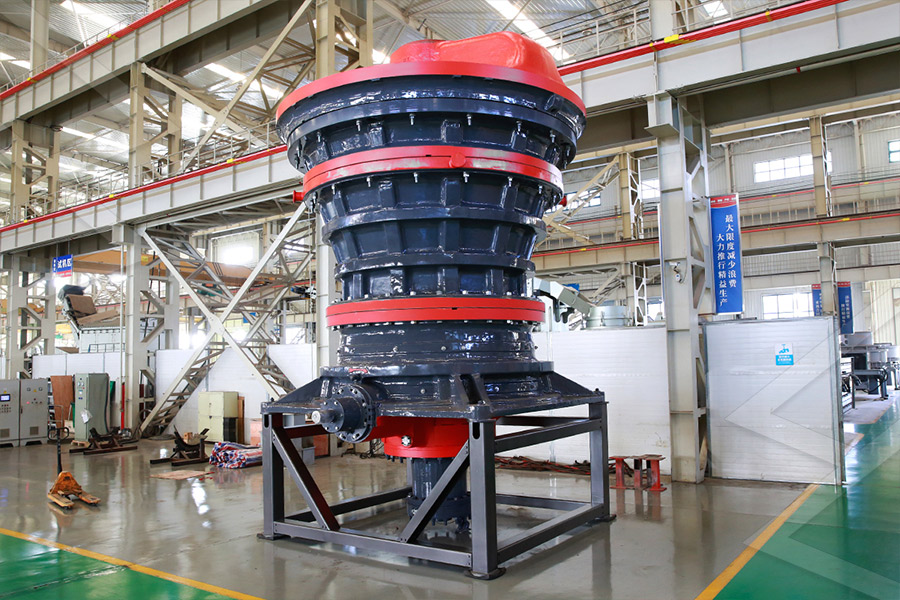

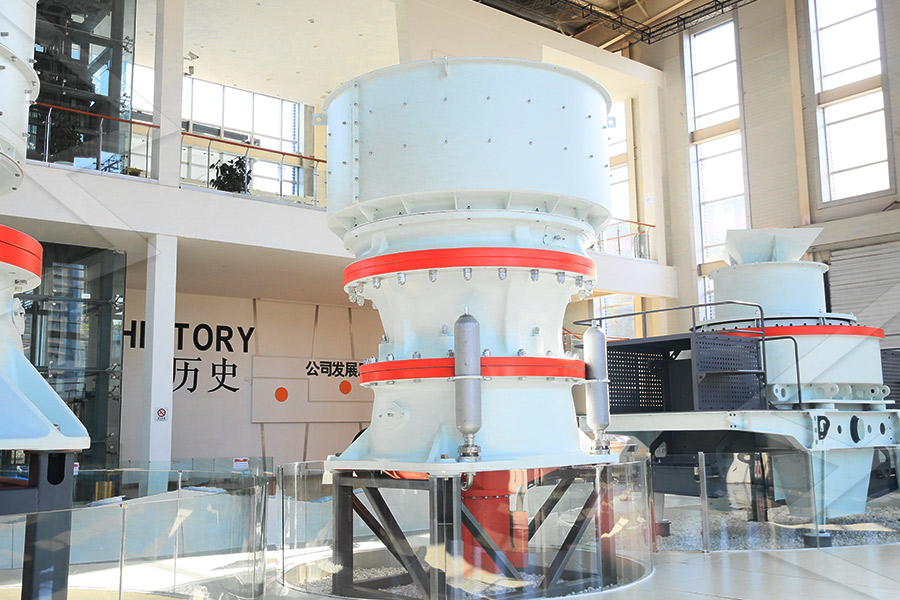

Home hybcrusher

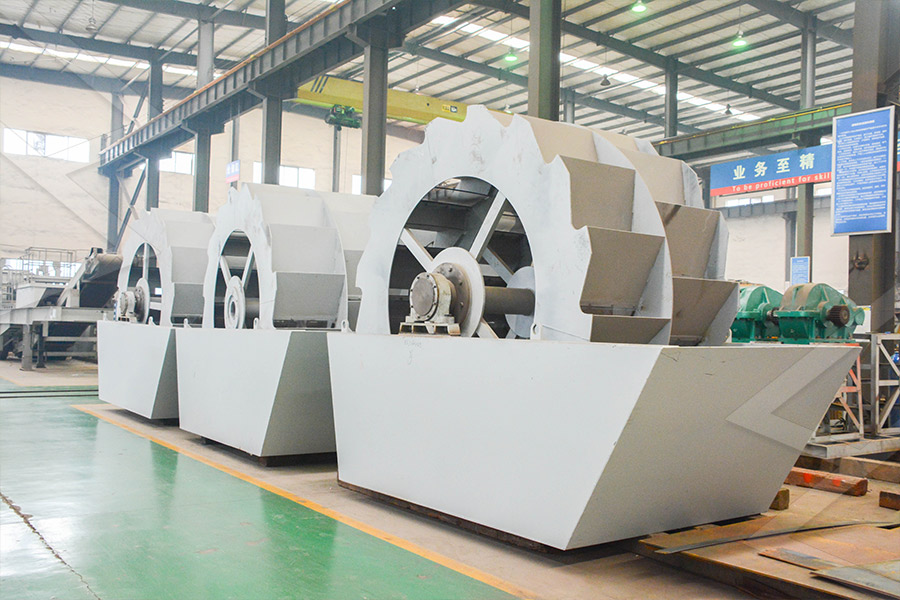

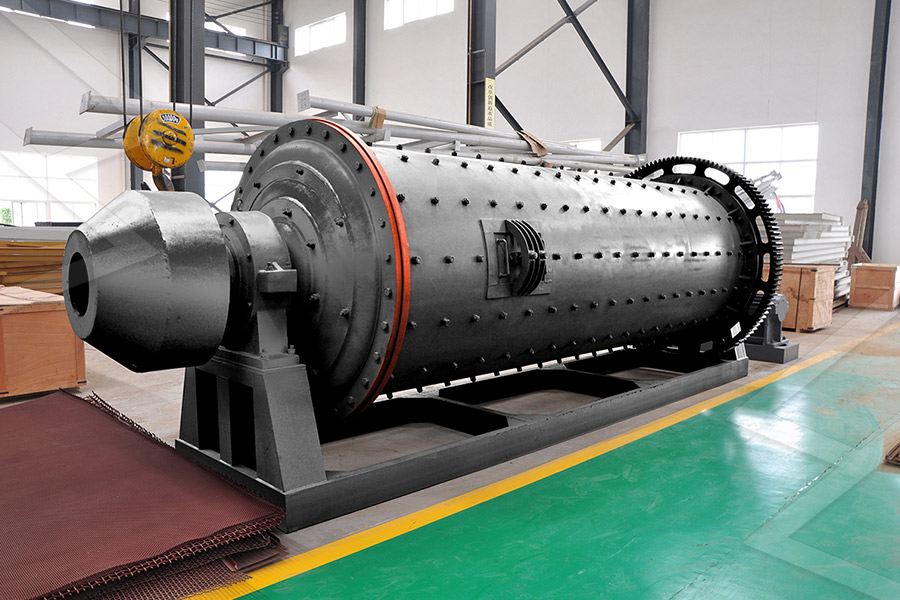

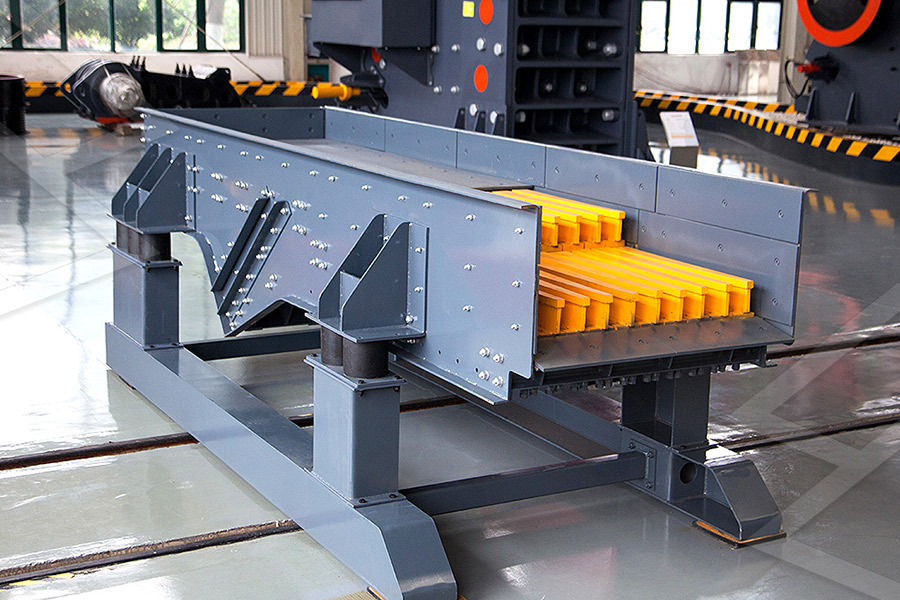

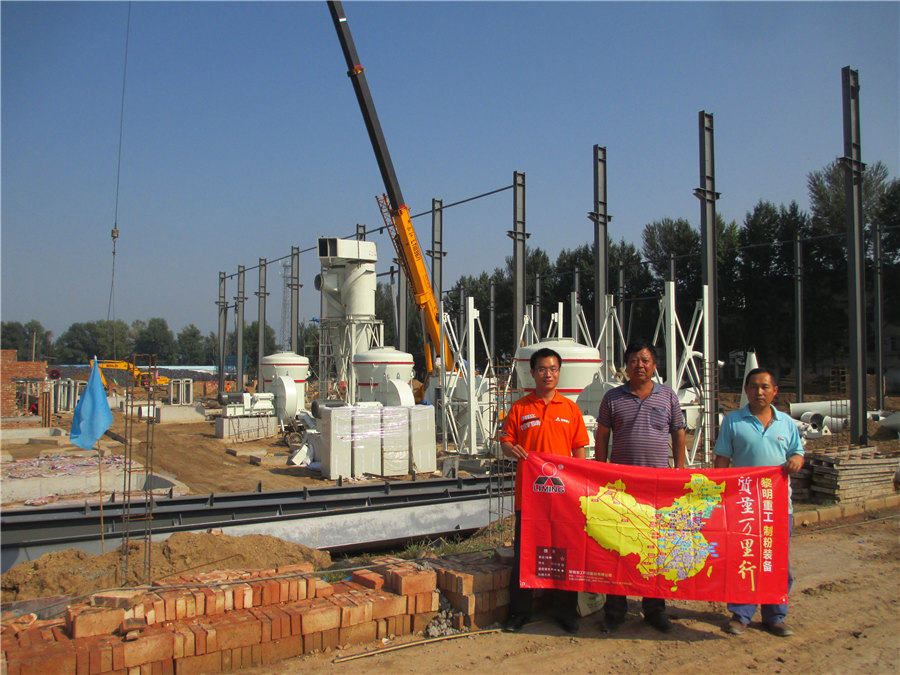

Our primary products include: Jaw Crusher, Cone Crusher, Ball Mill, Feeder, Vibrating Screen, and related spare parts GET AN INSTANT QUOTE NOW Checkout Our Hotselling Products Commit to train technicians and workers on site After the installation and commissioning are completed, the service engineers will not leave until they make sure 2020年7月24日 — lifetime of the jaw crusher Nordberg C Series jaw crushers are modular for quick, easy installation and commissioning in new plants and when replacing old jaw crushers This minimizes onsite engineering and fabrication, saves time, and reduces installation and structural costs The integral motor base reduces space requirements andNordberg® C SeriesTM jaw crushers Metso2021年5月6日 — A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and application of this machine are similar: the movable jaw has its maximum movement at the Jaw Crusher Working Principle 911Metallurgist2024年9月26日 — Model: VYKIN 8JC Configuration: Jaw crusher Power System: Direct drive Engine: 14HP gas engine Fuel Consumption: 026 – 052 gal/hr, 158 gal capacity Electrical Control: Yes, wireless remote VYKIN 8JC Mobile Mini Tracked Jaw Crusher

Crushing and Screening Handbook AusIMM

2021年6月24日 — portability between sites and fast installation, in addition to high crushing capacities Can be fi tted with jaw, cone or impact crushers, with or without screens, and equipped with open or closed circuit and discharge conveyors Mobile screens – trackmounted units for excellent mobility and high performance onsiteUsing Cone Ore Crusher in Secondly Crushing: In secondly crushing process,you can choose a fine jaw crushing machine or a cone crusher for sale A fine jaw crusher is generally used in small iron ore factories It has a simple structure and convenient maintenance However, its minimum discharge size is 40mmOre Crusher PE Series Jaw Type Ore Crusher AIMIXA jaw crusher is used for the firststage crushing, and an impact crusher is used for the secondstage crushing After the second crushing, gravel can be produced Onsite Installation Commissioning We can send engineers to your siteS to provide you with installation guidance and training services 4 Local Warehouses for Aftersale SupportLimestone Crusher Effective Machine To Make Sand Gravel2020年2月26日 — Operating instructions for jaw crusher type BB300 Retsch GmbH , 42781 Haan , RetschAllee 1 5 , Germany 2/7/2012 0002 07/02/2012 Retsch GmbH 2 Notes on the operating instructions These operating instructions for the jaw crusher type BB 300 provide Transport and installation Target group: Owners, carriers, operators PackagingOperating instructions for jaw crusher type BB300 NET

Nordberg® C Series™ jaw crushers Proven reliability and

2021年7月16日 — attached during installation C Series jaw crushers are also easy to install in underground mining applications as the modular design allows them to be dismantled for transportation in tight spaces Mounting the crusher does not require anchor bolts This is due to our unique solution where the crusher is standing on itsEssa JC2000 Jaw Crusher – a “workhorse” engineered to be the industry standard crusher in the geochemistry laboratory; Its two installation options offer improved flexibility Choose an upright, standalone configuration or a lowprofile benchmountable version Both can easily be configured to operate in a sampling station or pilot Laboratory and pilot plant Primary Jaw Crushers FLSmidth2024年9月17日 — Sa taille compacte, sa facilité de transport et son installation rapide font du concasseur Finlay® J1175 le concasseur idéal pour les applications mines, carrières, démolition et recyclage Terex Finlay J117 jaw crusher and C1545 cone crusher Veuillez activer les cookies de marketing pour cette fonctionJ1175 Mobile Jaw Crusher Terex Finlay2023年2月16日 — Jaw plates are an essential component of the jaw crusher and play a critical role in crushing the material Selecting the right jaw plates is crucial for optimizing the performance and longevity of the crusher By Jaw Plates: Everything You Should Know

.jpg)

Crushing Equipment Superior Industries US

2 天之前 — Liberty® Jaw Crusher Primary Maximum Feed Size 47″ (1,194mm) Maximum Reduction Ratio 6:1 Maximum Production Rate 1,595 STPH (1,446 MTPH) — Materials: Ore/Hard Rock, Quarried Stone, 2017年6月30日 — A review on the design and operations challenges of a single toggle jaw crusher is presented Strength and fracture toughness of the material to be crushed are intrinsic properties that determine (PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER 2023年2月21日 — A double toggle jaw crusher is a type of jaw crusher where the moving jaw is suspended from an eccentric shaft that is positioned on the top of the crusher The swing jaw is moved by a cam or pitman mechanism, acting like a lever or improper bearing installation The solution is to inspect and clean the bearings and lubrication system, and The Ultimate Guide to Jaw Crushing Machines: TypesThe sand making machine, also known as a sand crusher, is a device specifically designed for prod →; Date of release: How is jaw crusher customization reflected? The jaw crusher, as a commonly used ore crushing equipment, is widely applied in industries such →; Date of release: Maintenance Guidelines for Hammer sand making machine,hammer crusher,Jaw crusher

SANDVIK JAW CRUSHER SERIES Sandvik Mining and

2020年4月1日 — The Sandvik jaw crusher above is designed for the motor sizes listed in RPG and technical specifications This means that for harder materials, the crusher will have to be operated at larger settings to avoid overload of drive and/or motor Using oversized motors will lead to radically shorter crusher life and various mechanical problems5 天之前 — Easy to install kinglink's Jaw crusher has a range of bolton options, including an onboard motor base, and guarding for the flywheel and drives made from specially developed composite materials, which makes the unit simple to install as a crusher only or as a complete module in a new or existing plant The most versatile primary crusherStone Jaw Crusher Model (PE600X900 and PEX250X1200)Located in Xuyi, an ancient landscape city and the of lobster, and in the lower reaches of Huaihe River and the south bank of Hongze Lake, Jiangsu Zhongyou Machinery Co, Ltd is also in the vicinity of multiple traffic lines including XinyiYangzhou Expressway, ChangchunShenzhen Expressway, 344 National highway, NanjingLianyungang Expressway, thus Jaw Crusher Manufacturer, Impact Crusher, Cone Crusher Crushers Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 Jawcrusher Construction Jaw crushers are heavyduty machines and hence must be robustly constructed The main frame is often made from cast iron or steel, connected with tiebolts It is commonly made in sections so that it can be Jaw Crusher an overview ScienceDirect Topics

Types of Crushers Explained: Everything You Need to Know

2024年4月19日 — A singletoggle jaw crusher is simpler in design and is widely used because of its low cost and ease of maintenance On the one hand, the doubletoggle jaw crushers have a more complicated mechanism that creates a more uniform product size and a more efficient crushing It includes the purchase cost, installation cost, and 2014年4月1日 — The life of wear parts increases A jaw crusher usually wears more manganese steel per crushed tonne than a gyratory crusher The installation also calls for chutes and other bypass arrangements, Below the surface: Setting up an underground Czech company DS Holding purchased a Sandvik QJ341 jaw crusher and QE241 scalper to increase their operational capacity Looking to invest in mobile equipment to move around sites to recycle construction materials QJ241 Mobile Jaw Crusher Compact Jaw 2024年9月26日 — The Cedarapids® CRJ3042 plant combines the popular JW42 jaw crusher with a high stroke, 42” x 20’ (1067 x 6096 mm) vibrating grizzly feeder resulting in a high production portable crushing machine Learn More about CRJ3042; MJ42 The MJ42 features the rugged JW42 Jaw Crusher for high production applicationsCedarapids JW42 Jaw Crusher Terex MPS

.jpg)

Nordberg® C SeriesTM jaw crushers Metso

2020年7月24日 — lifetime of the jaw crusher Nordberg C Series jaw crushers are modular for quick, easy installation and commissioning in new plants and when replacing old jaw crushers This minimizes onsite engineering and fabrication, saves time, and reduces installation and structural costs The integral motor base reduces space requirements andPage 6 Nordberg C Series Jaw Crushers Table of Contents OPERATING INSTRUCTIONS 41 PREPARATIONS BEFORE STARTING41 42 STARTING THE CRUSHER Page 7 Nordberg C Series Jaw Crushers Table of Contents 54 INSTRUCTIONS FOR LIFTING A JAW CRUSHER WHEN REPLACING CRUSHER SUPPORT BRACKET DAMPERS 5 METSO NORDBERG C SERIES INSTRUCTION MANUAL Pdf 2023年3月2日 — C Series jaw crushers can be customized with options for any application Safe flywheel and drive guards protect operators from moving objects An optional integrated motor base allows installation of the crusher drive motor directly to the back of the crusher The motor moves in sync with the crusher so the Vbelt life is enhanced and Metso Crushing and screening solutions aggnetJaw crushers are widely used in mining smelting, building materials, roads, railways, water conservancy, and chemical industries There will be a strong vibration in the work, because of the large hardness of crusher materials Therefore, the work of the installation of a jaw crusher is very importantInstallation of Jaw Crusher Skills and Notes JXSC Mine

AIMIX Mobile Crusher For Sale Wheel Crawler Type

Mobile Crushing Plant For Sale A mobile crushing plant is a complete set of mobile equipment designed to crush and screen various materials onsite It consists of a vibrating feeder, a jaw crusher, an impact crusher or cone crusher, a vibrating screen, and belt conveyorsThe mobile crusher plant is highly flexible and can be easily relocated The singletoggle jaw crusher has less shafts and bearings compared to doubletoggle jaw crushers Only one toggle goes from the bottom of the swinging jaw back to the fixed point Doubletoggle jaw crushers In a doubletoggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear toggles up and downWhat Are Jaw Crushers and How Do They Work? OreflowNordberg® C Series™ jaw crushers are designed modular to save time and installation costs They can be installed within a few days, minimizing onsite engineering and fabrication The jaw crushers can be upgraded with crusher automation that enable monitoring and adjusting the settings of a feeder, crusher, and conveyor remotelyNordberg® C Series™ jaw crushers Metso