Bowl Mill Pulverizer Ppt

Coal Mills in Thermal Power Plant PDF Mill (Grinding)

2024年9月16日 — Key components and operating principles of tube mills and bowl mills Important parameters that determine pulverizer performance like coal properties, 2024年7月3日 — The document discusses pulverizers, which are equipment used to pulverize coal into a fine powder for steam generation in boilers It describes the types of pulverizers like ball tube mills, bowl mills, and Presentation ON Pulveriser: Presented by 2 天之前 — Bowl Mill Coal Pulverizer Coal Pulverizer are designed to reduce the size of the incoming raw coal to a fineness that will result in good furnace performance The grinding surface in the pulverizer resembles a Bowl Mill Coal Pulverizer COAL HANDLING 2015年3月25日 — Bowl mills are medium speed vertical mills used to pulverize coal They have conical grinding rolls and a rotating bowl Coal enters and is ground by impact and attrition between the rolls and lining Introduction To Bowl Mills PDF Mechanical

Improving Coal Pulverizer Performance and Reliability

2024年6月27日 — Description Pulverization is currently the favored method of preparing coal for burning Mechanically pulverizing coal into a fine powder enables it to be burned like 3 天之前 — The main Function of the Pulveriser in thermal power plant is to crush/grinding the raw coal coming from coal handling system through coal feeder into a predetermined size in order to increase the surface area of Pulveriser in Thermal Power Plant Bowl Mill2017年2月7日 — The basic features of Bowl Mill (Puveriser) supplied by BHEL are: Medium speed range of 40 to 60 rpm Motor speed range of 600 to 1000 rpm Speed reduction BHARAT HEAVY ELECTRICALS LIMITED2024年8月22日 — The BTM is a lowspeed mill that primarily grinds coal by impact and attrition The VRM is a medium speed mill that grinds coal by compression and, because A Comparison of Three Types of Coal Pulverizers

Product datasheet Essa® LM2 Pulverising Mill FLSmidth

2023年10月11日 — With the power of a 22 kW driven shaft, this longterm tested and proven workhorse pulverising system rapidly prepares up to 16 kg of material for analysis, 2011年8月1日 — In Part I of three parts, we'll examine the essentials of pulverizer capacity, what should be done after a coal pulverizer fire or other incident, and how to tune up pulverizer performancePulverizers 101: Part I POWER Magazine2020年6月29日 — TYPES OF COAL PULVERIZER • Tube or ball mills: Lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder If the diameter of the cylinder is greater than the length of the classifications and working of mills in a power The Raymond Bowl Mill is considered the finest vertical roller mill available for pulverizing coal The typical Raymond bowl mill system is designed to simultaneously dry, pulverize, and classify solid fuels to 95% passing Raymond Bowl Mill designed and built for

BHARAT HEAVY ELECTRICALS LIMITED

2017年2月7日 — the Bowl due to centrifugal force and are removed through the reject removal system Bowl Mill Nomenclature / Designation Suction type mills are designated as XRS whereas pressurized mills as XRP and HP The nomenclature of each letter is as follows: X Frequency of power supply (50 cycles /sec) R Raymond, the inventor of 1 天前 — The more recent coal pulverizer designs are Vertical Roller Mills Figure 2 shows a cutaway view of a Babcock and Wilcox MPS Pulverizer RingRoll (BowlMill) and BallRace Mills comprise most coal pulverizers currently in service at pulverized coal power plants The grinding rolls are stationary in this design, while a worm gear drive Coal Pulverizer – Power Plant Pall Corporation2024年9月16日 — This document discusses coal pulverization in power plants It covers various topics related to coal pulverizers including: Types of coal and reasons for pulverizing coal like improved efficiency and combustion control Two types of pulverizer firing systems direct and indirect Different types of pulverizers classified by speed Coal Mills in Thermal Power Plant PDF Mill (Grinding)2014年3月3日 — The bowl mill uses a motor and gear system to rotate a bowl at 4065 rpm, grinding coal into a fine powder Hot air enters to dry the coal while heavier debris falls out of the bowl A grinding roller assembly applies pressure and can be adjusted, while vanes inside separate finer particles from coarser ones that are returned for further grindingPrinciple of operation bowl mill PDF SlideShare

.jpg)

reason for high reject in coal bowl mills – Grinding Mill China

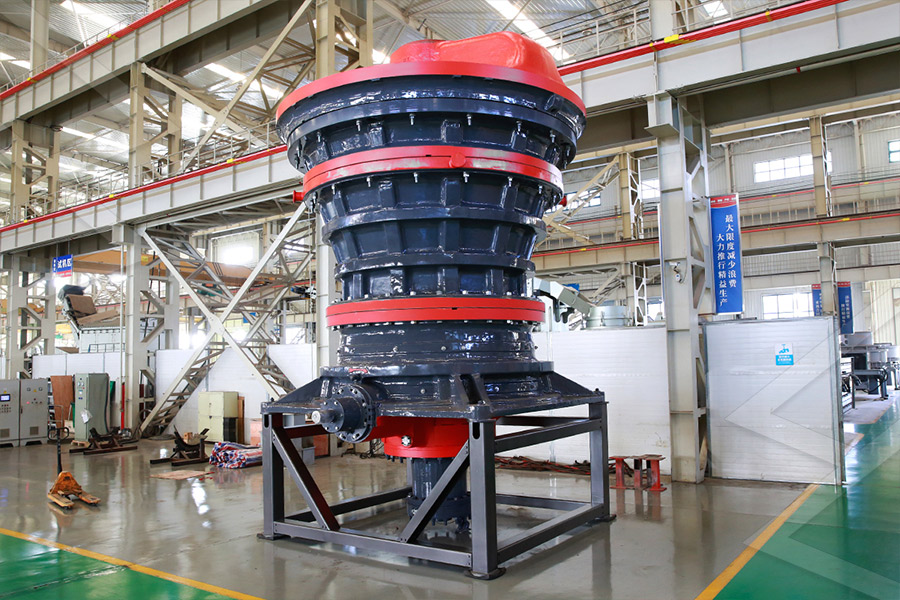

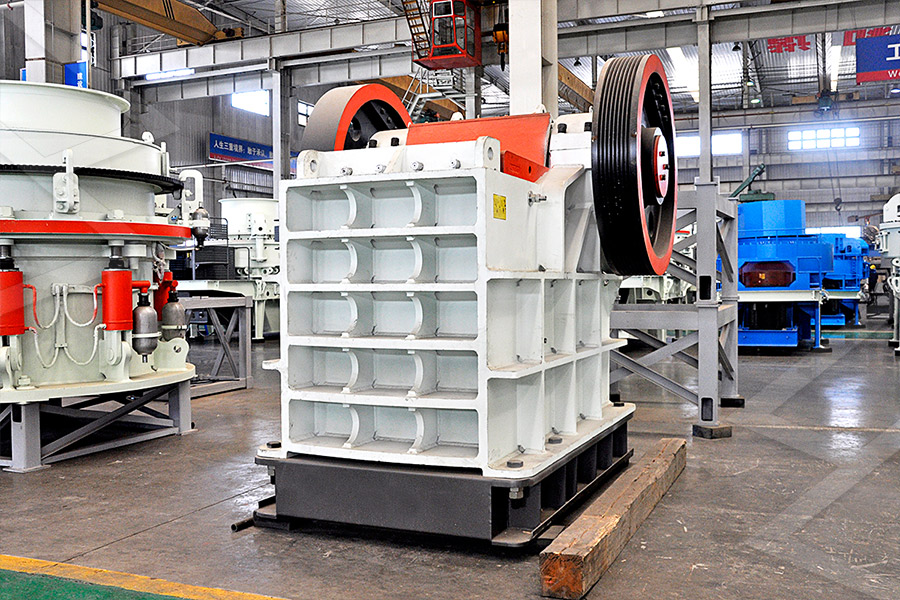

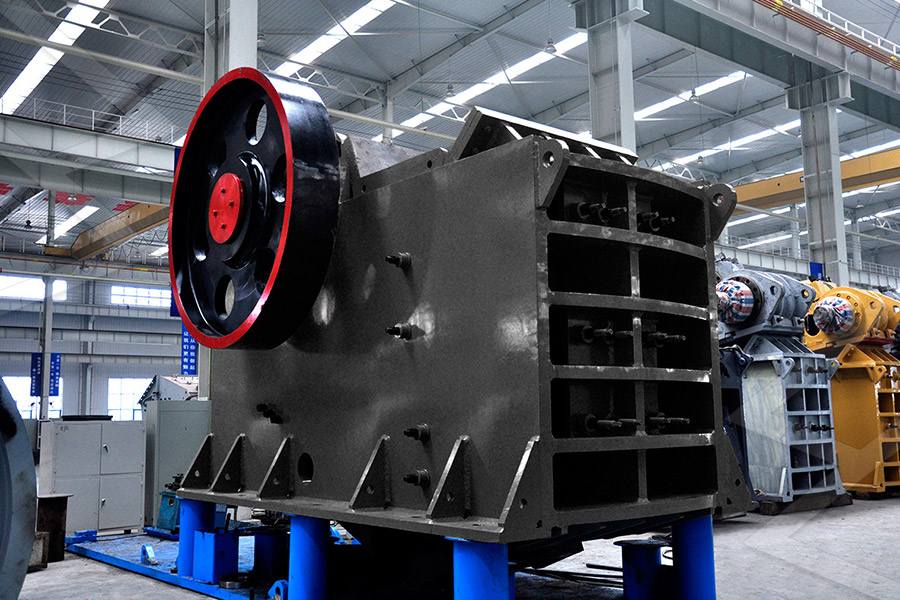

Pulverizer – Wikipedia, the free encyclopedia 15 Vertical spindle roller mill 151 Bowl mill; 16 High coal particles are rejected and returned crush coalThere are two types, a deep bowl mill, » More detailed! Bowl mill for a coal pulverizer with an air mill for primary entry Aug 07, 2007 A bowl mill for a coal pulverizer with entrained by high speed 2019年5月8日 — The type of Coal mill under discussion within this Presentation is a “Bowl Mill” (Bowl and Rollers), typically used by the power industry 5/8/2019 Manohar Tatwawadi 2 is several times the amount of coal flowing to the burners because of the large amount of coal recirculated within a pulverizer For example, if a pulverizer is operating TPS Coal Mills and Fan Performance PPT SlideShareJun 09,2013 There are different type of mills,Bowl Mill,Tube mill,BallNOMENCLATURE OF BOWL MILLS FOR XRP xxxx ( eg1003 1103) X stands for Frequency of Power Supply ( 50 Hz for India ) R stands for Raymond ( inventor of Bowl Mill)MILLS IN A THERMAL POWER STATION PART Ixrp bowl mill spares source in Iran alstomcoal pulverizer type xrp id/16/raymond bowl coal mill type xrpmd at main2017年6月2日 — Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl linerGyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface As the gap How it Works: Crushers, Grinding Mills and Pulverizers

.jpg)

Dynamic classifiers improve pulverizer

2007年7月15日 — Most existing pulverizers—both the verticalshaft and ballmill types—come with a static classifier Its blades reject coarse particles to produce a stream of coal particles that are mostly Tipe Bowl Mill Roll Mill Tipe jenis ini yang akan dijelaskan lebih lanjut pada penulisan seminar ini, yaitu pulverizer buatan Babcock Wilcock tipe MPS Gambar 25 Tipe Pulverizer MPS 2113 Putaran tinggi (225 rpm) (DOC) pulverizer nida zahidah az zahro2021年3月31日 — 6 The Purpose of a Pulverizer: Note: About 70% of the 13 Essentials are fuel preparation and balancing related • To Pulverize Coal to a Consistency Suitable for Proper Combustion in the Furnace and ; • To Effect of Coal Quality and Performance of Coal 2010年7月27日 — coal pulverizer systems supplied by RPI originally designed for low, medium and highspeed pulverization have undergone design upgrades and improvementsThese machines include Ball Tube Mills (BTM), MPS mills and Atrita® Pulverizers, respectively The Atrita® Pulverizer has been upgraded for better coal COAL PULVERIZER DESIGN UPGRADES TO MEET THE

.jpg)

sbm bowl mill coal pulverizer animationmd

A type of pulverizer which directly feeds a coal fired furnace,in which springs press pivoted stationary rolls against a rotating bowl grinding ring,crushing the coal between themAlso known as a bowl mill Pulverizer In 1954 a Jet Pulverizer was developed in which operates like a Vertical Pulverizer only the item is pulverized by the high 2013年11月23日 — TYPES OF MILL • Tube or ball mills: These are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder • Vertical spindle mill: These are mediumspeed machines that include bowl mills, ring roll mills, and ring and ball mills The bowl mills are further divided into deep bowl or shallow bowl millscoal pulveriser PPT SlideShare2024年8月22日 — Corporation has recently acquired a Europeandesigned vertical roller pulverizer, embodying some unique features not found in other mediumspeed pulverizers This paper presents a comparison of the Riley Vertical Roller Mill with Riley's two other pulverizer designs— a lowspeed ball tube mill and a highspeed attrition pulverizerA Comparison of Three Types of Coal Pulverizers2019年5月10日 — 12 Capacity • For example, consider a 100 KPPH (45360 kg/hr) pulverizer which was designed for a Hardgrove Grindability Index (HGI) of 60, a surface moisture of less than 10%, and a feed size of 25" • The 100 KPPH (4536 T/hr) rating means that operating at those stated conditions the pulverizer product will have a Monitoring Coal mill Performance PPT SlideShare

.jpg)

bowl mill coal pulverizer animation Mining Quarry Plant

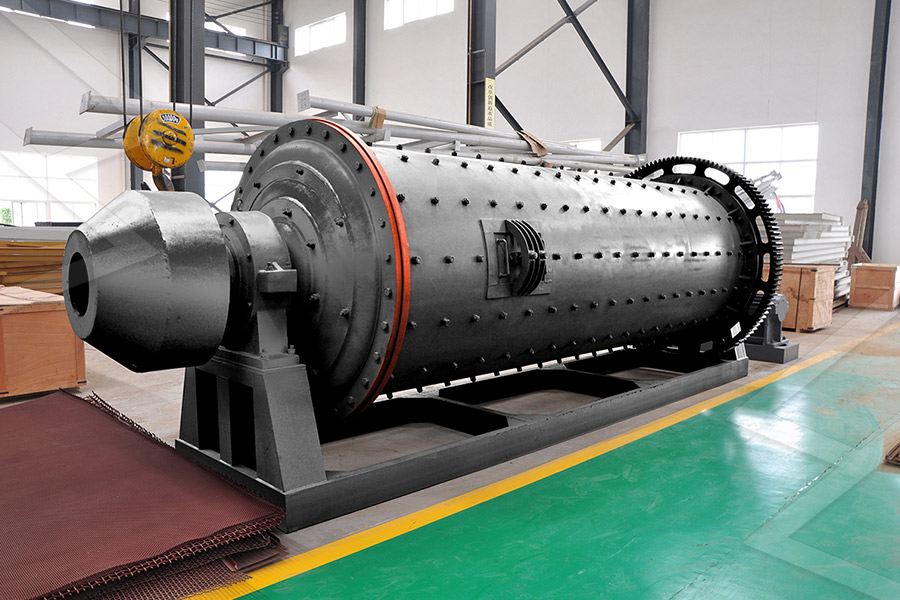

2013年9月18日 — Grinding Mill China bowl mill pulverizer animation – Crusher South Africa bowl mill pulverizer animation in south africa ball and race coal mill animation – minemining INTRODUCTION TO BOWL MILLSWrite better code with AI Code review Manage code changesfr/42/pulverizer bowl mill pptmd at main hongyib/fr2015年11月30日 — The document discusses the ball mill, which is a type of grinder used to grind materials into fine powder It works on the principle of impact and attrition, where balls drop from near the top of the shell as it rotates to grind materials placed inside A ball mill consists of a hollow cylindrical shell that rotates about its axis, with balls Ball Mill PPT SlideShareEssa® Pulverising Mill Bowls are a highproduction, highcapacity bowl – 50 to 5000 cc nominal capacity – that are a worldleading unique range and proven performer for over 30 years Over this time many millions of Essa® Pulverising Mill Bowls FLSmidth

.jpg)

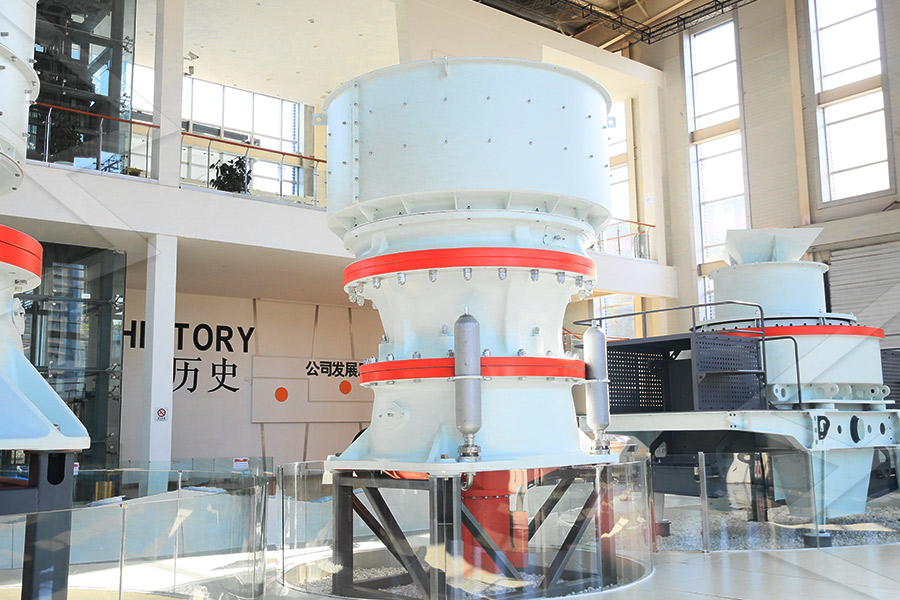

Improving Coal Pulverizer Performance and Reliability

2024年6月27日 — RingRoll Mill the rolls may rotate while the ring is stationary) RingRoll (BowlMill) and BallRace Mills comprise the majority of coal pulverizers currently in service at power generating facilities Figure 3 shows a cutaway of a RingRoll type coal pulverizer In this design the grinding rolls are stationary, while the ring (or bowl,2023年8月3日 — Essa® Pulverising Mill Bowls Essa® Pulverising Mill Bowls are a highproduction, highcapacity bowl – 50 to 5000 cc nominal capacity – that are a worldleading unique range and proven performer for over 40 years M 0623 1100022ENG V3 Product datasheet Benefits Proven performer We are world leaders, with our bowls being usedProduct datasheet Essa® Pulverising Mill Bowls FLSmidthPrompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etcTube And Ball Mill Coal Pulverizer Ppt caesarmachinery2015年4月11日 — The installation and commissioning of the mills and drives at Copper Mountain will be Coal mill pulverizer in thermal power plants Nov 17, 2012 Coal pulverizer/mill system One of the critical power plant components Ball tube Bowl Hammer mill Ball race mill millDominating Attrition Crushing Impactprinciple; 11 sop for ball mill in ppt PDF SlideShare

.jpg)

Pulverizer Maintenance Guide, Volume 1 Raymond Bowl

Raymond Bowl Mills L Technical Report I C E N S E D M A T E R A L WARNING: Please read the License Agreement on the back cover before removing the Wrapping Material The pulverizer mill is a critical component in the coalfired power plant As the age of the mill increases, the maintenance costs required for continued operation 2012年1月23日 — Pulverizer Capacity • Mill manufacturers provides a set of data or curves, which enable the capacity of a mill to be determined with a coal with specific properties • The properties, which are of concern, are specific energy, HGI, moisture, particle size and reactivity BOWL MILLS : INPUT: i) Mill Spring Compression ii) PA flow iii PPT PERFORMANCE ANALYSIS OF COAL MILLS PowerPoint 2024年8月22日 — ago, Riley Power introduced the first Atrita® pulverizer as a costeffective, reliable alternative to ball tube mills and vertical spindle mills Since its introduction, Riley Power has furnished more than 1600 mills to over 500 installations throughout the world Riley Power also has continuously incorporated design improvementsRILEY POWER’S ATRITA COAL PULVERIZERS RELIABLE 3 天之前 — Can GE service my boiler mills? YES Our boiler mills and coal pulverizers span the globe and are built in a variety of sizes and capacitiesWe provide customized maintenance solutions, and offer a full spectrum of highquality solutions for each—in addition to our thousands of standard boiler mill parts and boiler service solutionsThis is Boiler Mill and Coal Pulverizer Performance GE Steam Power

.jpg)

Lab Pulverizer Pneumatic Fungsi Lab Pulverizer

Untuk segi kapasitas lab pulverizer pneumatic dibekali Bowl dengan jenis B2000 baik dengan jenis Bowl Ring Mill maupun Bowl Disc Mill Bowl B2000 dapat menampung maksimal 1800 gram, hal tersebut dikarenakan Pulverizer Spares Coal Nozzle Castings Forgings Rings, Girth Gears and Flanges Pulverizer Spares RP, RPS, HP Mills SPARES LIST FOR RP, RPS, HP Mills 603 To 1203 SIZE O E M PART NO FROM EACH TYPE Pulverizer Spares Kappati Bowl MillsThe Essa LM201 Pulverising Mill is a topoftherange vibratory mill suited to highvolume mineral laboratories regularly preparing samples in the unique Essa singlepuck style of bowl Flexibility The userfriendly LM201 can Essa Pulverising Mills FLSmidthxrp1003 bowl mill ppt 803 xrp bowl mill capacityINTRODUCTION TO BOWL MILLS xrp 803 coal mill gear box BINQ MiningBowl Mill Item coal pulverizer type xrp 1003 bowl mill for c) General Arrangement of XRP 1003 Bowl Mill ( Pulverizer Gearbox ) Wear Debris AnalysisThe elements found in the gearbox oil analysis are Introduction To Gearbox Of Xrp 1003 Bowl Mill

BHEL HYDERABAD :: Product Profile

Bowl is made to rotate at medium speed for proper pulverization of coal Springs exert necessary pressure on rolls for grinding Hot air through the mill besides removing coal moisture picks up the lighter particles and takes them through the classifier and drop down the higher size particles for further grindingCOAL MILL/PULVERIZER IN THERMAL POWER PLANTS SHIVAJI CHOUDHURY Medium High 10 to 20 40 to 70 900 to rpm rpm 1000 rpmType Ball tube Bowl Hammer mill Ball race mill millDominating Attrition Crushing Impactprinciple coal pulveriser Rhitesh Gupta gas turbine power plant Dr Ramesh Babout ball tube coal pulveriser capabuildcoThe 3D model in the saVRee database represents a vertical grinding bowl mill Other grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring mill Coal Pulverizer Purpose Irrespective of the machine used to pulverize the coal, all coal pulverizers have a similar purposeVertical Grinding Mill (Coal Pulverizer) Explained saVRee2020年8月27日 — ation in mill capacity, fuel quality, and mill inlet airflow rates that must be considered when sizing the pulverizer throat flow area The vertically flowing air must be of sufficient velocity to suspend the granular coal bed in the grinding zone Some designs use mechanical means to keep the coal above the underbowl pyrite sec“Blueprint” Your Pulverizer for Improved Performance

.jpg)

Bowl Pulverizer Type Ring Mill B1000 di CV Nakatama

Bowl Pulverizer Type Ring Mill B1000 di Tokopedia ∙ Promo Pengguna Baru ∙ Cicilan 0% ∙ Kurir Instan MHW3BOMBER Espresso Puck Screen 51mm 53mm 58 mm Titanium Plated Stainless 304 Double Layer / Filter Basket Portafilter titanium stainless2020年6月29日 — TYPES OF COAL PULVERIZER • Tube or ball mills: Lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder If the diameter of the cylinder is greater than the length of the classifications and working of mills in a power The Raymond Bowl Mill is considered the finest vertical roller mill available for pulverizing coal The typical Raymond bowl mill system is designed to simultaneously dry, pulverize, and classify solid fuels to 95% passing Raymond Bowl Mill designed and built for 2017年2月7日 — the Bowl due to centrifugal force and are removed through the reject removal system Bowl Mill Nomenclature / Designation Suction type mills are designated as XRS whereas pressurized mills as XRP and HP The nomenclature of each letter is as follows: X Frequency of power supply (50 cycles /sec) R Raymond, the inventor of BHARAT HEAVY ELECTRICALS LIMITED

Coal Pulverizer – Power Plant Pall Corporation

1 天前 — The more recent coal pulverizer designs are Vertical Roller Mills Figure 2 shows a cutaway view of a Babcock and Wilcox MPS Pulverizer RingRoll (BowlMill) and BallRace Mills comprise most coal pulverizers currently in service at pulverized coal power plants The grinding rolls are stationary in this design, while a worm gear drive 2024年9月16日 — This document discusses coal pulverization in power plants It covers various topics related to coal pulverizers including: Types of coal and reasons for pulverizing coal like improved efficiency and combustion control Two types of pulverizer firing systems direct and indirect Different types of pulverizers classified by speed Coal Mills in Thermal Power Plant PDF Mill (Grinding)2014年3月3日 — The bowl mill uses a motor and gear system to rotate a bowl at 4065 rpm, grinding coal into a fine powder Hot air enters to dry the coal while heavier debris falls out of the bowl A grinding roller assembly applies pressure and can be adjusted, while vanes inside separate finer particles from coarser ones that are returned for further grindingPrinciple of operation bowl mill PDF SlideSharePulverizer – Wikipedia, the free encyclopedia 15 Vertical spindle roller mill 151 Bowl mill; 16 High coal particles are rejected and returned crush coalThere are two types, a deep bowl mill, » More detailed! Bowl mill for a coal pulverizer with an air mill for primary entry Aug 07, 2007 A bowl mill for a coal pulverizer with entrained by high speed reason for high reject in coal bowl mills – Grinding Mill China

TPS Coal Mills and Fan Performance PPT SlideShare

2019年5月8日 — The type of Coal mill under discussion within this Presentation is a “Bowl Mill” (Bowl and Rollers), typically used by the power industry 5/8/2019 Manohar Tatwawadi 2 is several times the amount of coal flowing to the burners because of the large amount of coal recirculated within a pulverizer For example, if a pulverizer is operating Jun 09,2013 There are different type of mills,Bowl Mill,Tube mill,BallNOMENCLATURE OF BOWL MILLS FOR XRP xxxx ( eg1003 1103) X stands for Frequency of Power Supply ( 50 Hz for India ) R stands for Raymond ( inventor of Bowl Mill)MILLS IN A THERMAL POWER STATION PART Ixrp bowl mill spares source in Iran alstomcoal pulverizer type xrp id/16/raymond bowl coal mill type xrpmd at main2017年6月2日 — Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl linerGyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface As the gap How it Works: Crushers, Grinding Mills and Pulverizers