Names Of Crushing Plant With Micro Wave Heating System Design

.jpg)

Microwave Heating Applications in Mineral

2012年11月7日 — If both the solvent and the substance to be dried are transparent to microwaves (ie, no heating by microwave energy), then a suitable microwave heat accelerator, such as carbon, magnetite or In the present research, the microwave heating behaviours of over forty ores have been studied at the benchscale These results were used to generate a database, from which a unique Microwave treatment of ores development 2023年4月19日 — affect the crushing of rocks which impact the rawmaterial production is still lacking In this research work microwaveassisted crushing of a kimberlite ore is studied TRANSFORMING POWER DRAW TREND OF ORE 2024年9月18日 — prediction of the long term performance of the plant Using dynamic simulation of crushing plants will also need a lot more information then what normally is CRUSHING PLANT PROCESS OPTIMISATION AusIMM

Mechanistic Study of a Microwave FieldControlled

2022年8月12日 — static crushing agent between microwave heating and conventional heating, under the premise of ensuring the same total energy output of conventional 2023年12月15日 — Microwave heating generates both comparatively larger cracks and smaller cracks in kimberlite ore, which directly impact the power draw trends during Application of instantaneous power draw analysis to 2022年11月25日 — Development of control systems is important for the operating conditions in a crushing plant Realtime optimization is a relatively new field in aggregate THESIS FOR THE DEGREE OF L ENGINEERING IN2022年8月10日 — In this research, an instantaneous power draw analysis is applied to detect the microwave heating impact on the particle breakage mechanism during singleroll TRANSFORMING POWER DRAW TREND OF ORE CRUSHING BY APPLYING MICROWAVE HEATING

Study on Magnetite Ore Crushing Assisted by Microwave

2021年10月14日 — High energy consumption in ore crushing brings great challenges to the mining industry Microwave irradiation provides a promising solution for rock breakingA research group now known as the Julius Kruttschnitt Mineral Research Centre at the University of Queensland has been working since 1962 on the simulation, optimization and control of mineral treatment processes The initial work was on the grinding and classification processes This work has been very successful in the optimization (Lynch, [PDF] The Simulation of Crushing Plants with Models 2024年9月24日 — The life of the mine is a key element in the design of any crushing plant Shortterm mine lives (three to eight years) require a very careful approach to design, layout and construction Since the crushing plant’s structure and enclosure can represent the largest single cost element in a primary crushing plant, it is imperative to optimize Crushing Plant Design and Layout Considerations 911 Radiant floor heating offers a blend of comfort and efficiency that few other heating methods can match The success of any radiant heating system depends on meticulous planning taking into account factors like outside How to Design Radiant Floor Heating and

10 Types of Home Heating Systems and How to Choose One

2024年9月11日 — Home heating systems are designed to increase the temperature inside a house by tapping thermal energy from a fuel source, and then transferring it to living spaces There are several types of home heating systems used to provide heat in residential homes, and each broad type has more specific variations Some HVAC systems share 2021年6月24日 — Plant automation systems – monitor and control all crushing, screening, storing and conveying with realtime accuracy Maintain maximum production capacity by adjusting process parameters online Original wear and spare parts – using original Metso wear parts is the key to a successful crushing process The design of our certifi edCrushing and Screening Handbook AusIMM2018年10月19日 — This document presents a proposal for designing an expert system in the Gabriela Mistral Division’s crushing plant belonging to Codelco (Chile) with the objective of maximizing stacked tonnage, allowing the improvement of operational variables that directly interact with the crushing process In addition, this study considers the impact that occurs Design and Evaluation of an Expert System in a Crushing Plant 2014年1月1日 — A statement of the problem of crushing plant optimisation is formulated and a genetic evolutionary algorithm has been included in the software in order to facilitate the optimisation processThe Factors affecting the performance of crushing plant operations

.jpg)

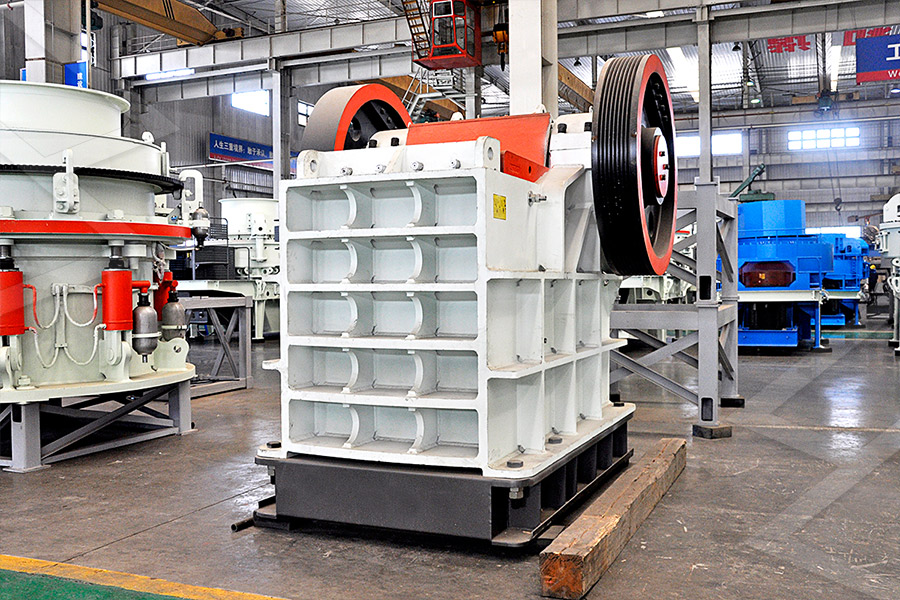

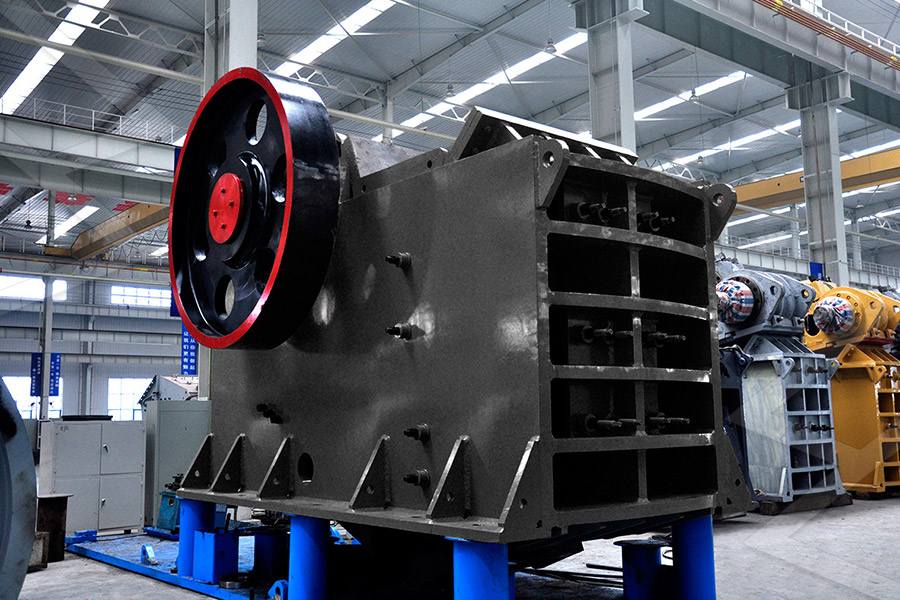

Design of a crushing system that improves the crushing

2016年2月10日 — up This paper addresses the critical design parameters that will increase the crushing capacity of the plant to 35 tonnes per hour There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The paper analyses all of these steps Keywords Gold mining, crushing, Zimbabwe, jaw O serviço do Google, oferecido sem custo financeiro, traduz instantaneamente palavras, frases e páginas da Web do português para mais de cem outros idiomasGoogle Tradutor2019年10月25日 — This research includes optimization of aggregate production of the stone crushing plant using fuzzy modelling The investigation includes onsite aggregate testing and fuzzy logic implementation Fuzzy modelling is a type of computerized reasoning used to simulate the real plant operation In this work, a lot of agent degree information for Optimization and Simulation of Operation Performance in Crushing Plants 911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has Metallurgists Mineral Processing Engineers

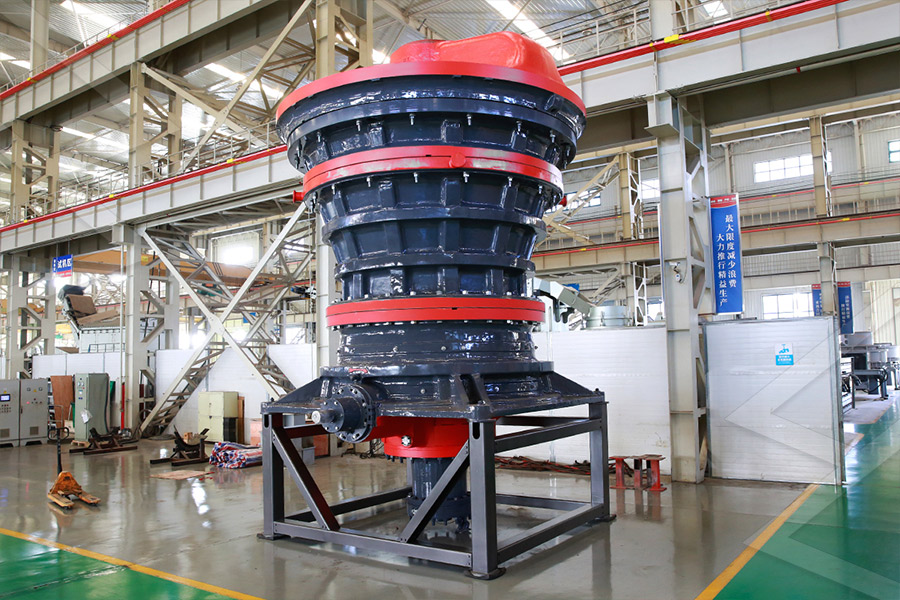

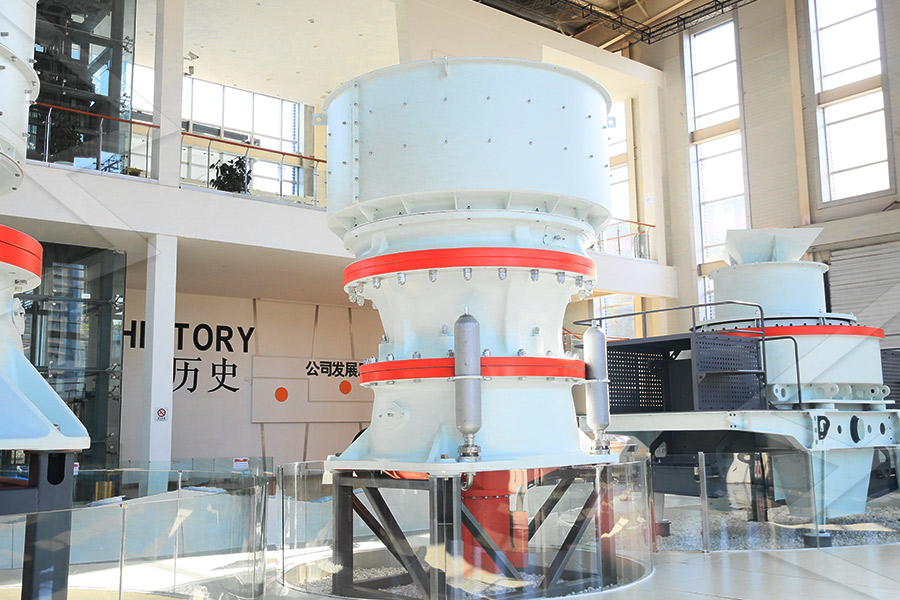

Crushing Technologies thyssenkrupp Polysius

As it will be necessary to move the crusher in the future, Semen Bima has opted for a semimobile design of the crushing plant The plant capacity is 1000 t/h with a product grain size of 50 mm The detail engineering of the 2023年2月23日 — Introduction An aggregate crushing plant is a machine that processes a wide range of raw materials into highquality aggregate, which is used in a variety of construction applications such as roads, buildings, The Ultimate Guide to Designing an Efficient 2024年6月28日 — Infloor radiant heating systems—both electric and hydronic—use thermal radiation and electromagnetic waves to heat your home Electric wires or waterfilled tubes are installed underneath the flooring and warm a room by directly heating the floor instead of the air Hybrid heating system: $2,500–$10,000; Infloor radiant heating Types of Home Heating Systems (2024 Guide) This Old House2021年4月26日 — This guideline provides the minimum knowledge on design of micro hydro systems in regional countries A hydro system is usually classified by size (generating capacity) and the type of scheme (runofriver, storage, etc) The classification of hydro system varies from region to region and it is believed that there is no agreed definitionMICRO HYDROPOWER SYSTEM DESIGN GUIDELINES

KS8: How to design a heating system (2006) (pdf) CIBSE

The guidance maps the heating design process, with flowcharts illustrating the design steps sequence, and puts heating system design in the context of the overall building process It also outlines the key design procedures for each design step, provides guidance on data requirements and sources, and highlights potential issues and problem points2023年2月28日 — Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of The Complete Guide to Primary Crushing, Secondary CrushingA welldesigned hydronic heating system is composed of several key components that work together to provide efficient, comfortable heat throughout a home Understanding each element is crucial for homeowners interested in hydronic heating system design Boiler The boiler is the heart of a hydronic heating systemThe Ultimate Guide: Hydronic Heating System Design for this paper proposes current development in mini hydro power production and its contribution to the near future distributed generation However there are some problems which come in contact while implementing the power generation unit Some of these problems faced are high water head, large flow of water, high cost of civil works, large covered area and its Cost efficient Mini hydro plant with low water head whirlpool design

.jpg)

Types of Crushers Explained: Everything You Need to Know

2024年4月19日 — The crushing process is commonly conducted in several stages Each stage of the crushing process implements a different type of crusher to gradually reduce the size of the material The first step is crushing the material by using larger crushers that can reduce the material into smaller sizes that will be used in the next stage2012年1月1日 — A new microreactor with surface acoustic wave (SAW) heating system was presented The microreactor is comprised of surface acoustic wave heating source, a PDMS microvessel and a metal microvesselA Microreactor With Surface Acoustic Wave MicroHeating SystemDeliver the rock crusher onsite, set it up, drop its legs and start tipping raw materials for maximum crushing capability Add the MICRO Screen Plant and MICRO Conveyor for the entire MICRO Plant, producing and sorting three sizes at 300400 tons per day, loading directly to the dump trucks and run and loaded by a single operator with remote Portable Jaw Crushing Plant Senya 3 Senya Crushers2013年4月1日 — 1 Introduction Crushing plant’s design relay on accurate plant simulations Crushing plants are designed to be able to produce certain throughput on predefined specification (ie a certain particle size distribution) and a certain particle size distribution while operating at a reasonable cost and at efficient energy consumptionModelling and simulation of dynamic crushing plant

.jpg)

Design and Analysis of a Microcombined Heating and Power System

Microcombined heating and power system of proton exchange membrane fuel cell (mCHPPEMFC) as a green clean heat supplied and distributed energy system has a huge advantage in improving the traditional energy utilized method and energy step utilization In this paper, we analyzed the electric and thermal demand of domestic residential and 1 Desmet Ballestra, Buenos Aires, Argentina 2 Desmet Ballestra, Zaventem, Belgium * Correspondence: vgibon@desmetballestra Received: 11 February 2020 Accepted: 7 September 2020 Abstract A minimal residual oil content in the meal coming out of the hexane extractor is a clear benefit for a crushing plant; the more oil yield the better Overview of the soybean process in the crushing industry2021年12月3日 — Heating plays a vital role in science, engineering, mining, and space, where heating can be achieved via electrical, induction, infrared, or microwave radiation For fast switching and continuous applications, hotplate or Peltier elements can be employed However, due to bulkiness, they are ineffective for portable applications or operation at Microheater: material, design, fabrication, temperature 2008年8月27日 — A crushing plant system comprising crushers, screens, conveyors and other equipment can be difficult to operate to the highest possible efficiency, but a new computer tool has been developed to help optimize this process, as Per Svedensten, plant simulation specialist with Sandvik Mining and Construction, explainsCrushing Plant Performance Optimization AggNet

.jpg)

Crushing 101 – Different types of crushers for distinctive needs

2020年12月17日 — Mechanized crushing has existed for 150 years Despite the fine differences between the equipment, at the end, they all have the same objective: to reduce the size of rocks and, of course, to supply the market with products as varied as gravel for construction or iron ore for the steel sector2020年6月16日 — Uniform microwave heating system design and evaluation with an orthogonally slotloaded array waveguide SeongHyeop Ahn, SeongHyeop Ahn In the conventional microwave applicator with rectangular waveguides, the heating uniformity is low due to various hot and cold spots Using the proposed slotloaded array waveguide Uniform microwave heating system design and evaluation 2023年5月15日 — With rapid developments in industrialization, numerous high earthrock dams, waste rock piles and tailing dams have been built worldwide The particle skeletons of these engineering structures are Mechanical behavior and particle crushing of irregular 2021年5月1日 — The ability of the EM waves to heat a material depends critically on its dielectric properties Although essential in the design of a MW reactor, there is a lack of data about these properties owing to the extreme temperature conditions at which they must be determined and the requirement of specific composition and structure of the materials Design of a pilotscale microwave heated chemical vapor

.jpg)

Crushing Screening Plant Design Factors

2016年4月14日 — Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons In order to keep the flowsheet simple, and because of the use of the forced 2020年1月16日 — Renewable energy resources are preferred as compared to conventional energy resource due to their environment friendly nature Microhydropower plant is one of the best renewable energy sources that provides electricity to hilly and rural areas Microhydropower plants are mostly installed at natural heads and runoff rivers Lack of a Design and implementation of an electromechanical control system 2024年9月18日 — CRUSHING PLANT PROCESS OPTIMISATION P Svedensten1 ABSTRACT Design of processes in order to fi nd the most ef fi cient solution to a speci fi c task is a dif fi cult problem Often the number of solutions are large and the optimal solution is therefore diffi cult to identify Crushing plant process design is no exception CRUSHING PLANT PROCESS OPTIMISATION AusIMM2013年11月18日 — According to the onedimensional shock wave theory, the simple empirical formulae for graded honeycombs to predict the plateau stress are given under highimpact velocities These results will provide some useful guides in the multiobjective optimization dynamic design and shock energy absorbing control of sandwich structuresDynamic crushing behavior and energy absorption of

10 Types of Home Heating Systems To Know Forbes

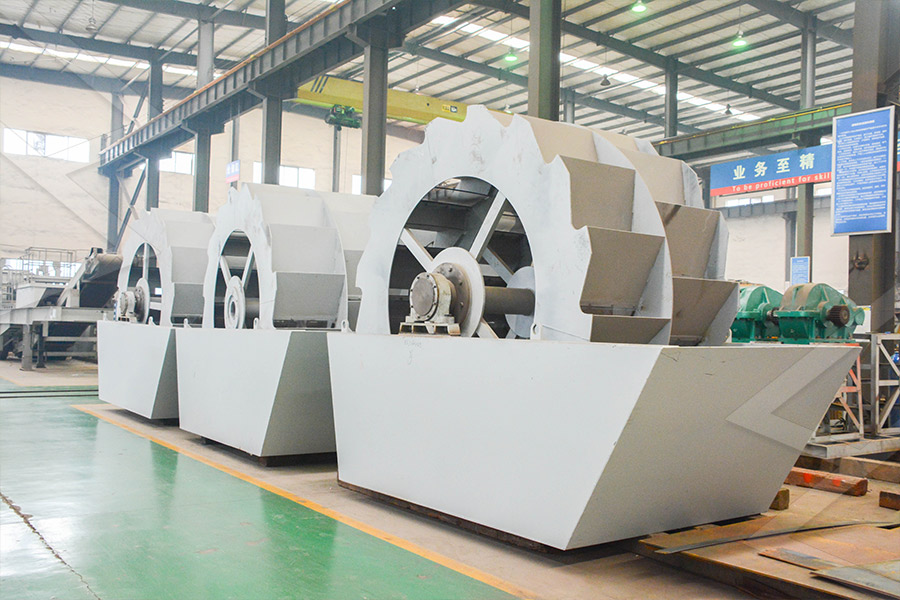

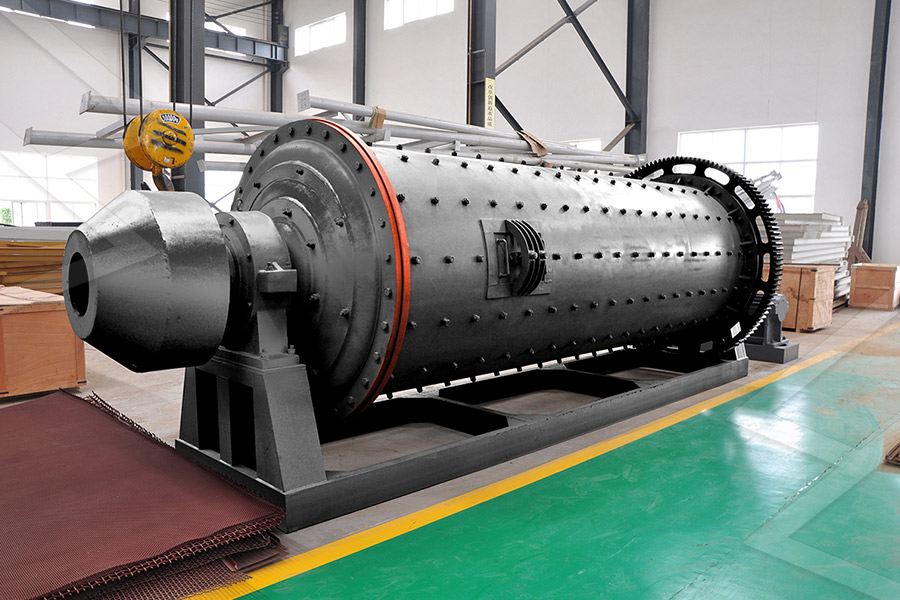

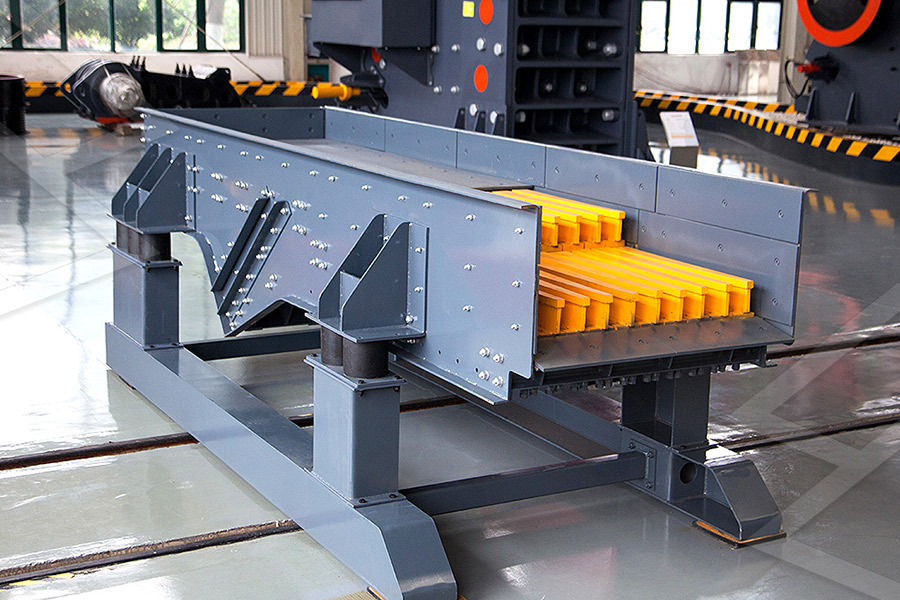

2024年3月14日 — 1 Furnace Forced air distribution systems are by far the most common type of home heating systems They use a furnace with a blower fan that delivers heated, conditioned air to the house’s 2019年5月27日 — 21 Specifications of the Crushing Plant The mineral derived from both the opencut and groundbased exploitation must be prepared in a crushing plant; then, if necessary, acid is added to achieve a controlled grain size to ensure a good permeability coefficient of the solution Crushing is a unitary operation of size reduction by theDesign and Evaluation of an Expert System in a Crushing 2024年3月1日 — A stone crushing plant needs essential primary crushers like jaw and gyratory crushers as well as finecrushing equipment like impact crushers and ball mills Other critical heavyduty machines for the effective operation of a stone mill include the belt conveyors, vibration feeder, vibrating screens, and a central control system for all these What Machines Do Stone Crushing Plants Need? Fote Specific objectives are: i) to get detailed knowledge, which can be used for assessing the plant performance and control development, ii) to collect a bunch of system data, which can be used for calculating plant availability and utilization, and finally iii) to better describe the bottlenecks of crushing plant, which can lead to production delays(PDF) Field monitoring and performance evaluation of crushing plant

(PDF) Microwaveassisted Extraction of Functional Compounds from Plants

2023年6月14日 — SEM micrographs of morphological changes in Agave angustifolia Haw stems with microwave treatment Plant fragments size 0074 mm, longitudinal view, (a) and (b) show the untreated samples, and (c A research group now known as the Julius Kruttschnitt Mineral Research Centre at the University of Queensland has been working since 1962 on the simulation, optimization and control of mineral treatment processes The initial work was on the grinding and classification processes This work has been very successful in the optimization (Lynch, [PDF] The Simulation of Crushing Plants with Models 2024年9月24日 — The life of the mine is a key element in the design of any crushing plant Shortterm mine lives (three to eight years) require a very careful approach to design, layout and construction Since the crushing plant’s structure and enclosure can represent the largest single cost element in a primary crushing plant, it is imperative to optimize Crushing Plant Design and Layout Considerations 911 Radiant floor heating offers a blend of comfort and efficiency that few other heating methods can match The success of any radiant heating system depends on meticulous planning taking into account factors like outside How to Design Radiant Floor Heating and

10 Types of Home Heating Systems and How to Choose One

2024年9月11日 — Home heating systems are designed to increase the temperature inside a house by tapping thermal energy from a fuel source, and then transferring it to living spaces There are several types of home heating systems used to provide heat in residential homes, and each broad type has more specific variations Some HVAC systems share 2021年6月24日 — Plant automation systems – monitor and control all crushing, screening, storing and conveying with realtime accuracy Maintain maximum production capacity by adjusting process parameters online Original wear and spare parts – using original Metso wear parts is the key to a successful crushing process The design of our certifi edCrushing and Screening Handbook AusIMM2018年10月19日 — This document presents a proposal for designing an expert system in the Gabriela Mistral Division’s crushing plant belonging to Codelco (Chile) with the objective of maximizing stacked tonnage, allowing the improvement of operational variables that directly interact with the crushing process In addition, this study considers the impact that occurs Design and Evaluation of an Expert System in a Crushing Plant 2014年1月1日 — A statement of the problem of crushing plant optimisation is formulated and a genetic evolutionary algorithm has been included in the software in order to facilitate the optimisation processThe Factors affecting the performance of crushing plant operations

.jpg)

Design of a crushing system that improves the crushing

2016年2月10日 — up This paper addresses the critical design parameters that will increase the crushing capacity of the plant to 35 tonnes per hour There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The paper analyses all of these steps Keywords Gold mining, crushing, Zimbabwe, jaw O serviço do Google, oferecido sem custo financeiro, traduz instantaneamente palavras, frases e páginas da Web do português para mais de cem outros idiomasGoogle Tradutor2019年10月25日 — This research includes optimization of aggregate production of the stone crushing plant using fuzzy modelling The investigation includes onsite aggregate testing and fuzzy logic implementation Fuzzy modelling is a type of computerized reasoning used to simulate the real plant operation In this work, a lot of agent degree information for Optimization and Simulation of Operation Performance in Crushing Plants